Menü

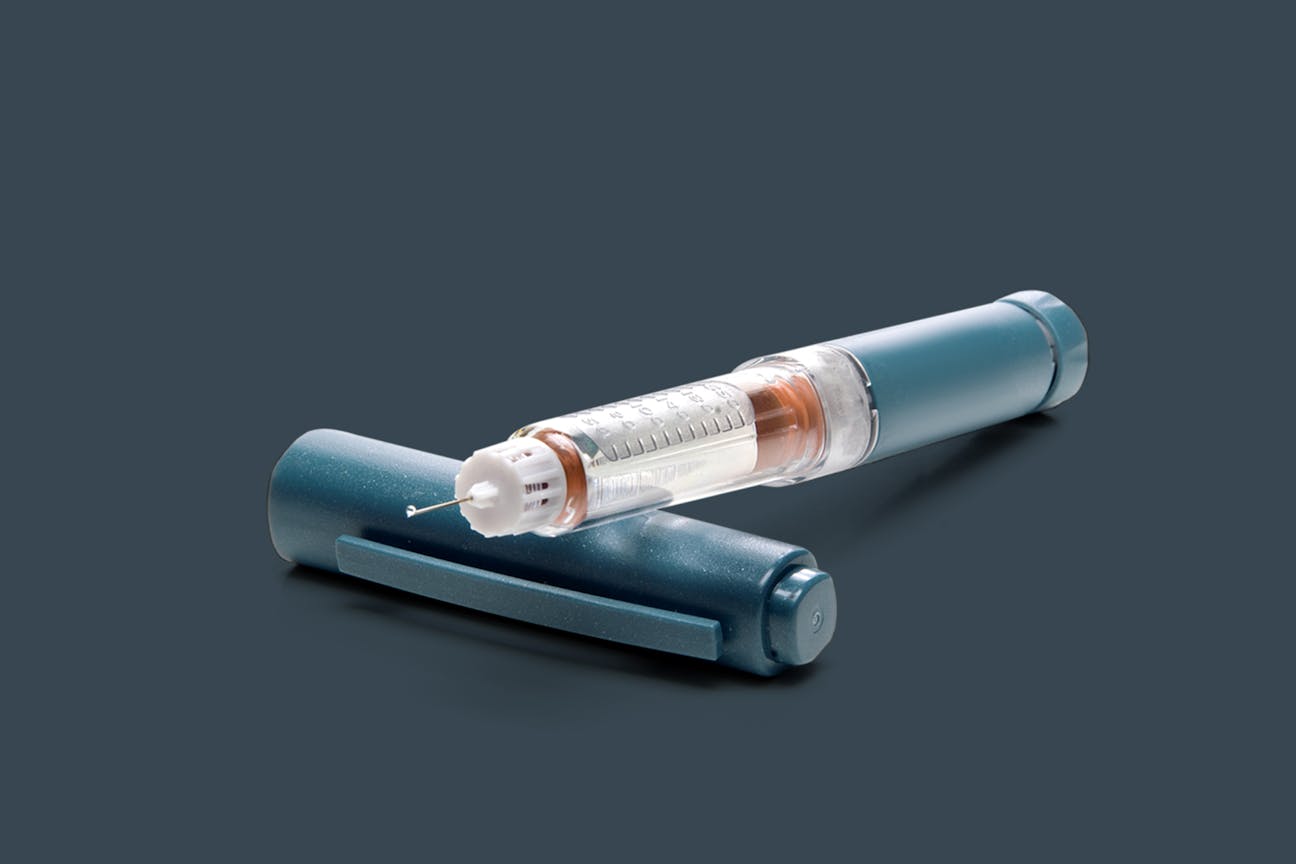

Insulin Pen Inspection Reliable Detection of Assembly Errors, Quality Assurance

Automation Improves Efficiency and Patient Safety

Insulin Pen Inspection

For Taking Away and Passing On

カタログ

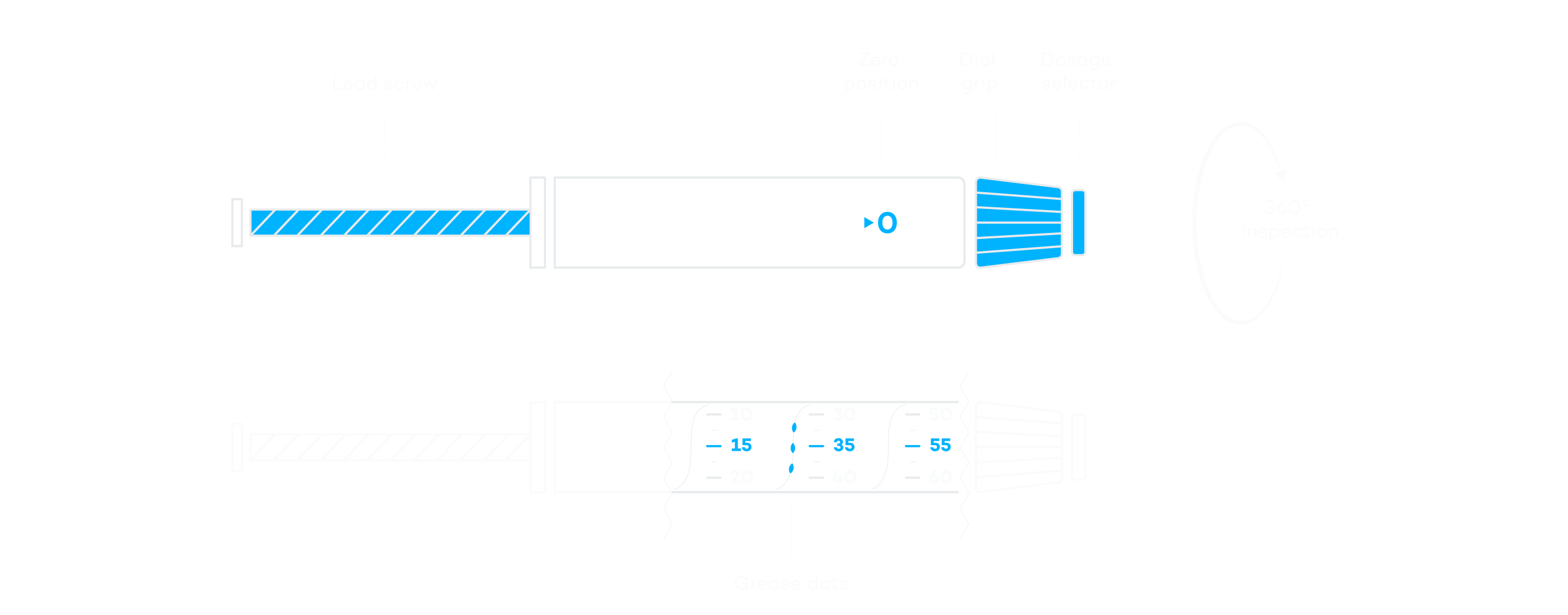

VINSPEC HEALTHCARE for Insulin Pens

カタログ

VINSPEC HEALTHCARE—Inline Pharmaceutical/Medical Device Inspection