Air Freight Measurement Optimal Airplane Loading

Automatic Freight Measurement

Air Freight Measurement

Reliable Freight Measurement – and Correct Invoicing!

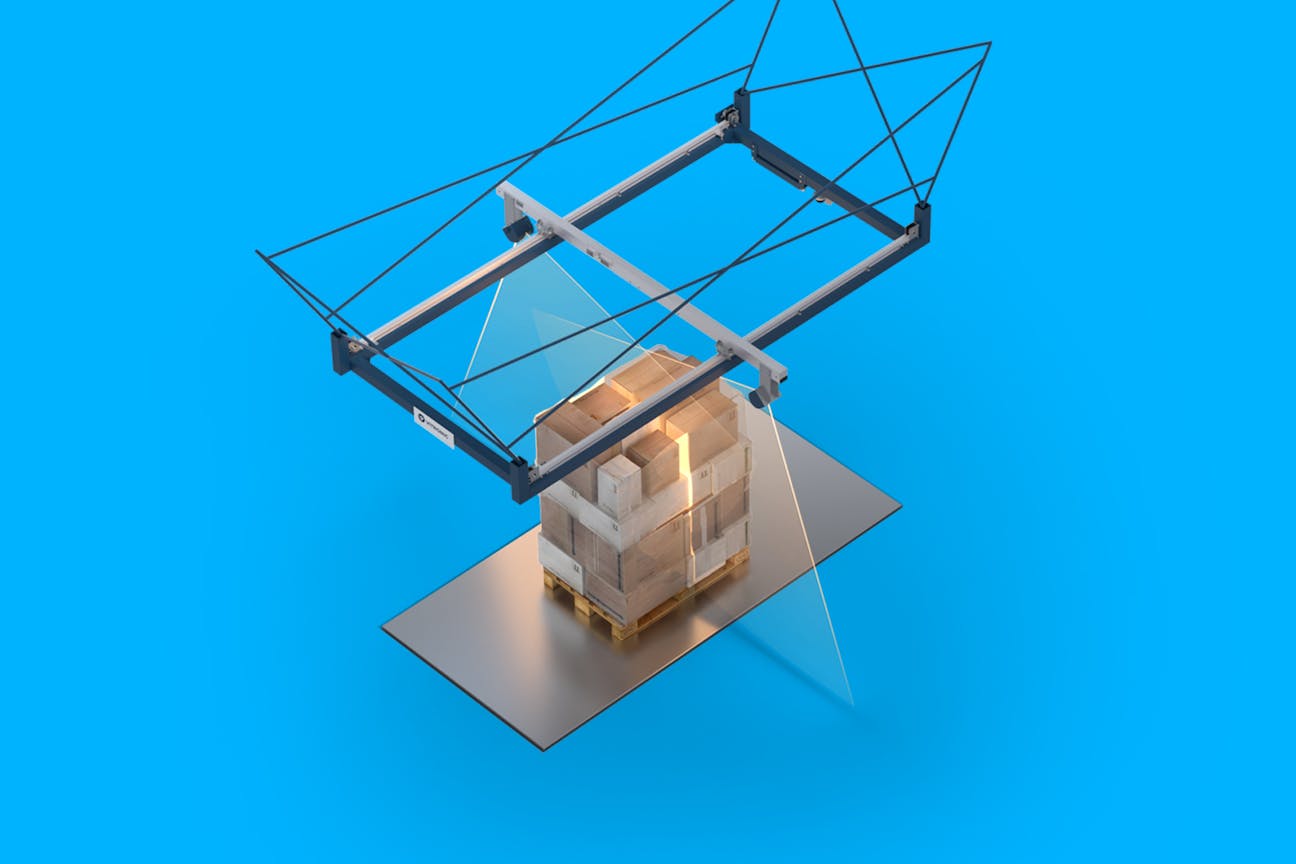

Technology for Precise and Certifiable Freight Measurement

Cargo space in airplanes is expensive and loading is a very complex issue. As a result, cargo companies rely on precise and certifiable measurements of the dimensions of packages and pallets. However, manual processes take too long and require trained staff. Freight values declared as too low are also problematic. The solution is to automate your freight measurement and ensure full transparency of “your” air freight.

Our Solutions for Air Freight Handling

Loading an airplane is akin to solving a complicated puzzle. Optimal use must be made of even the tiniest of spaces, and every kilogram must be included in the calculation of the plane's take-off weight so that its center of gravity is balanced. With certified Auto-ID systems, you can prepare for a successful take-off.

Certified Capture of ULD Pallets – in Just 6 Seconds!

Our Auto-ID systems enable error-free, certifiable freight measurement. This results in processes that are accelerated to the max.

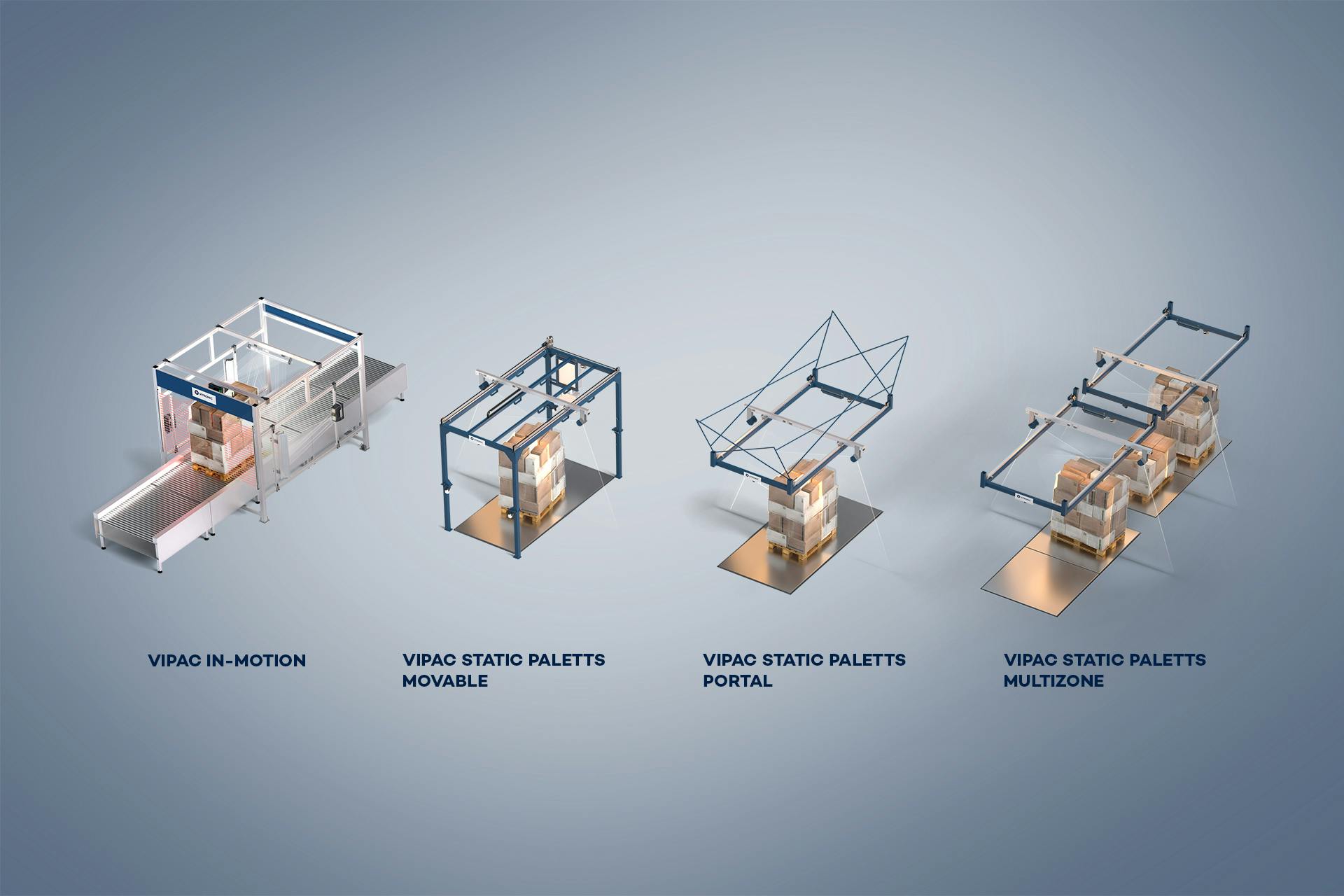

Even with the VIPAC STATIC PALLETS semi-automated system, you can achieve time savings of 75 percent compared with manual capture. And our fully automated VIPAC IN-MOTION systems are even faster. Which allows you to also manage express freight in the blink of an eye.

- 25s manual data capture

- 6s VIPAC STATIC PALLETS

- 3s VIPAC IN-MOTION

Error-Free Data

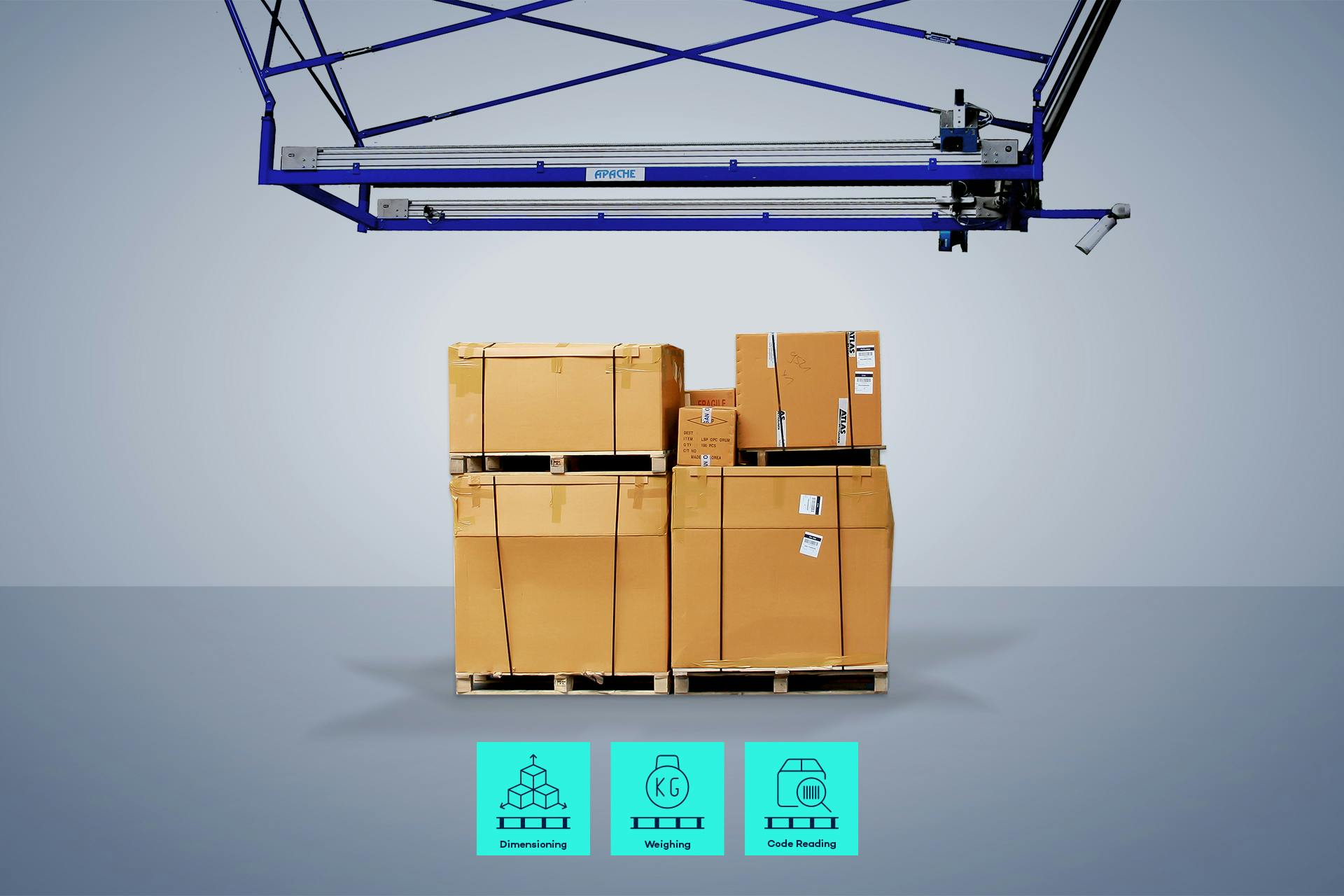

Automated air freight handling not only results in faster processes. Automation also means error-free capture of all data in a single work step. Every ULD pallet has its own data record. The Auto-ID system can create an optional image of the complete pallet and save it to the archive. It simply doesn’t get more transparent than this.

Auto-ID systems capture:

- Dimensions and weight

- All codes

- Plain text optional

- up to 400pallets/h VIPAC IN-MOTION

Correct Freight Invoicing – Including for “Black Sheep”

You need correct and authoritative data when invoicing your customers. Our Auto-ID systems are certifiable (legal for trade). Which means that the measurement data for weight and columns are certified—keeping you on the safe side.

In addition, you’ll never fail to spot incorrect details of palletized freight. VIPAC STATIC PALLETS checks your “black sheep” so that you can then provide the customer with correct, certified dimension data.

- OIML/MID/NTEP certified

Putting Data to Good Use

You need reliable freight measurements because, when it comes to air freights, every centimeter and every gram counts. Our certified freight data enables optimal loading of ULD pallets and ULD containers so you don’t waste any precious space.

Our Auto-ID systems also detect pallets that have not been loaded uniformly, protrusions, and deviations from the pallet standard, and check whether freight is stackable.

What about the question of liability after freight is handed over? Error-free data records with images also provide clear evidence in relation to the quantity, weight, volume, and integrity of each freight shipment.

For Efficient Freight Measurement

Our systems adapt to meet your requirements. With VIPAC STATIC PALLETS, you can choose between portal solutions with measuring corridors for one or more pallets or a movable solution that can be flexibly positioned in the hub. Our VIPAC IN-MOTION systems are also available for pallets that are conveyed automatically. An optional X-ray module can also be integrated.

In Brief

Carsten Astner

Sales Logistics Automation- carsten.astner@vitronic.com

- Telefon

- +49 151 6896 2325

Follow me

Measuring Air Freight—Transparently, Automatically, and Efficiently

In Brief

- Automated capture of codes, volumes, and dimensions

- Certified invoicing

- 75% time saving compared with manual capture

- Optimal warehouse and transportation planning

- Simplified Claim Management

- Seamless track & trace