Menü

Order Picking and Outgoing Goods Inspection Speed Up Outgoing Goods Processes

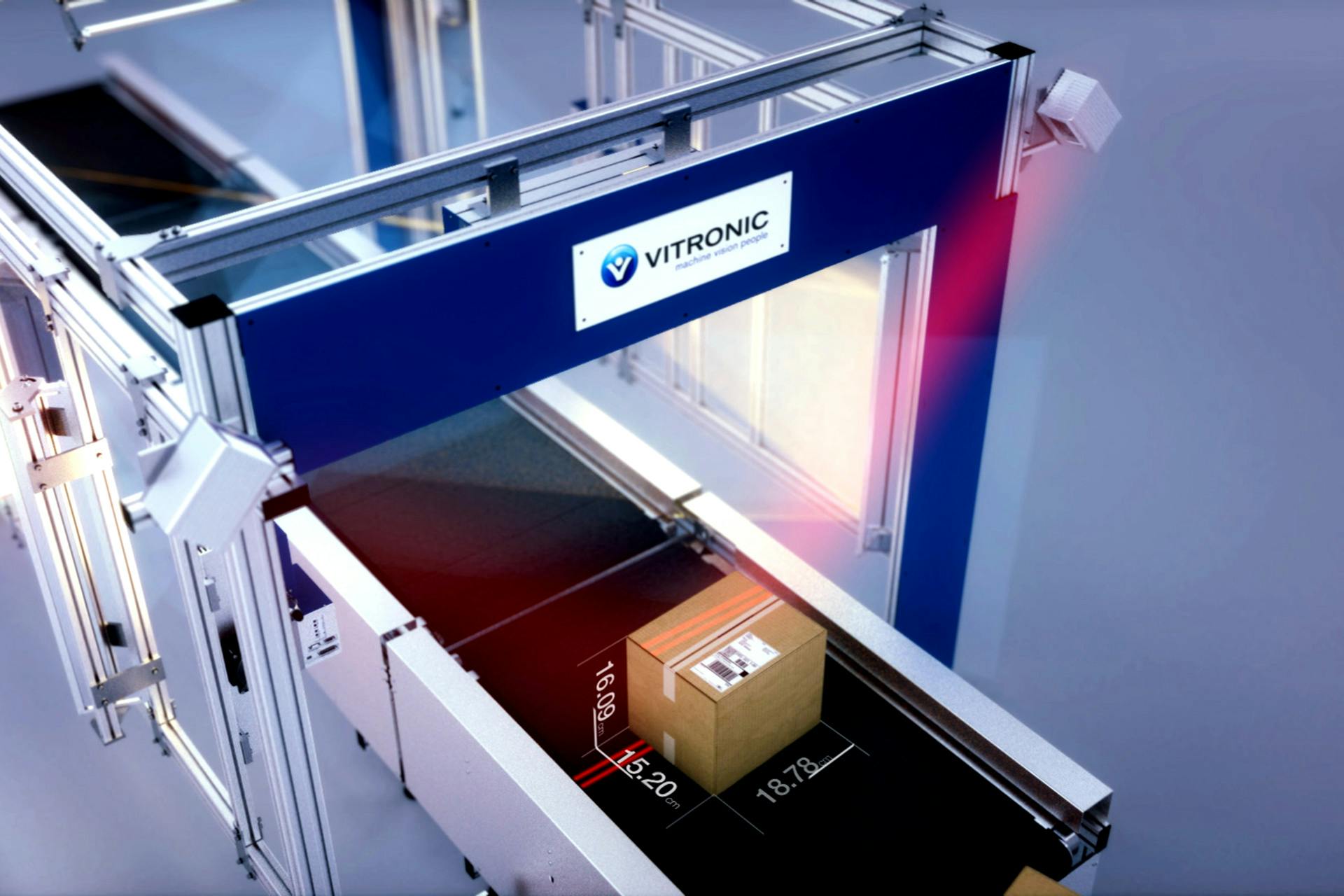

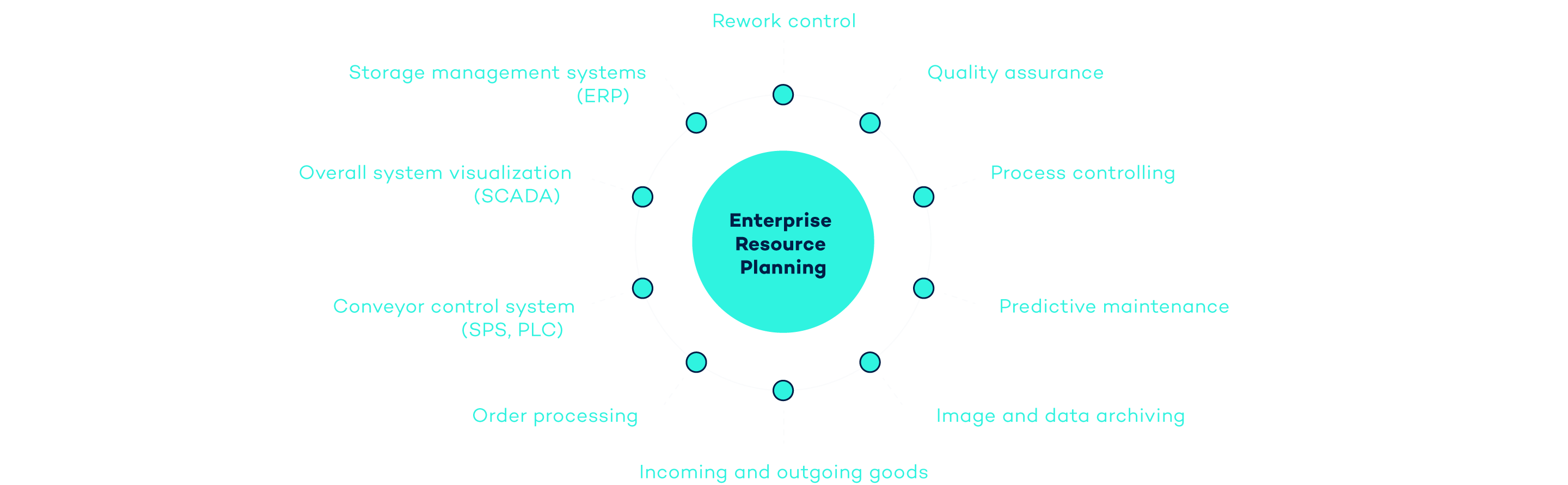

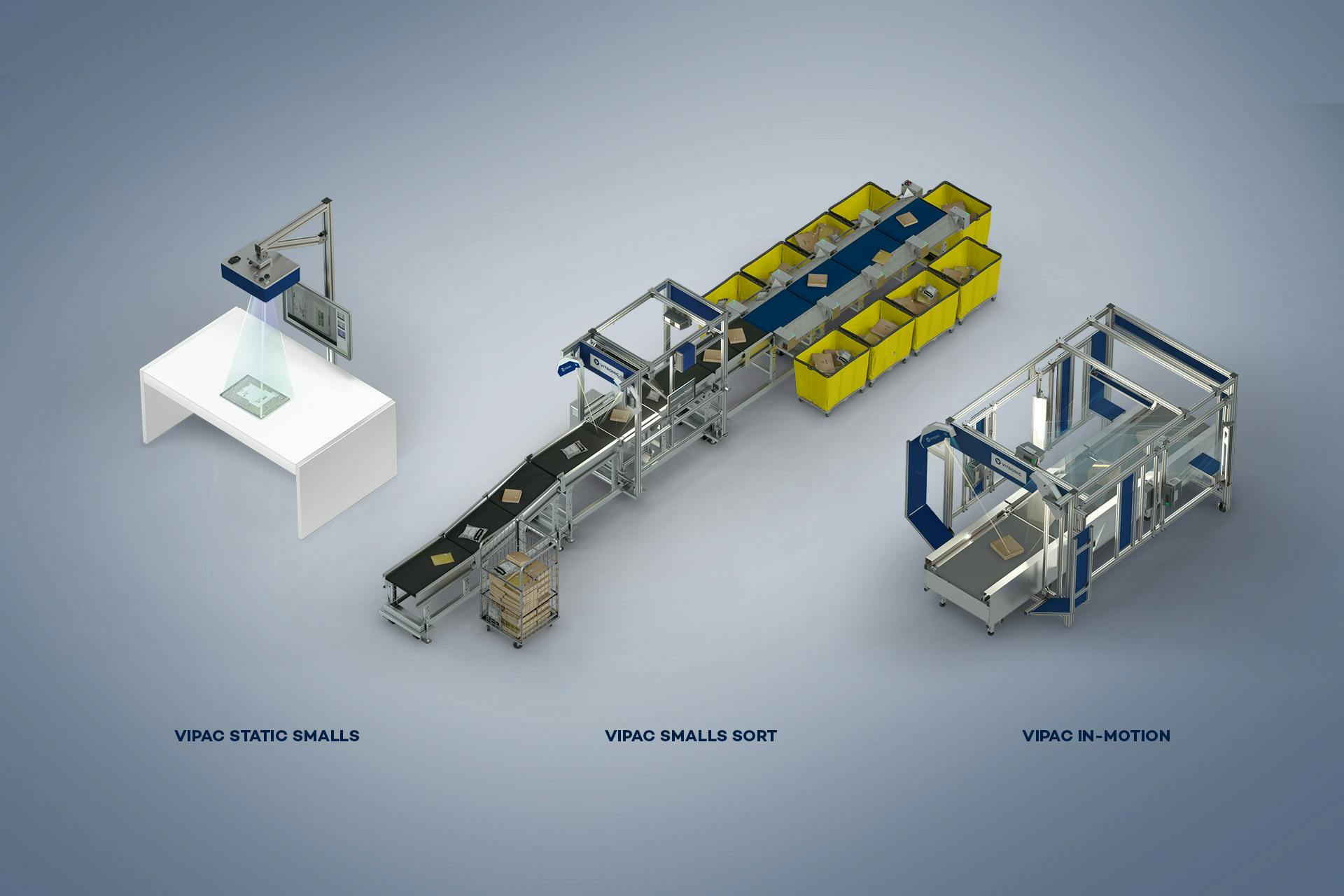

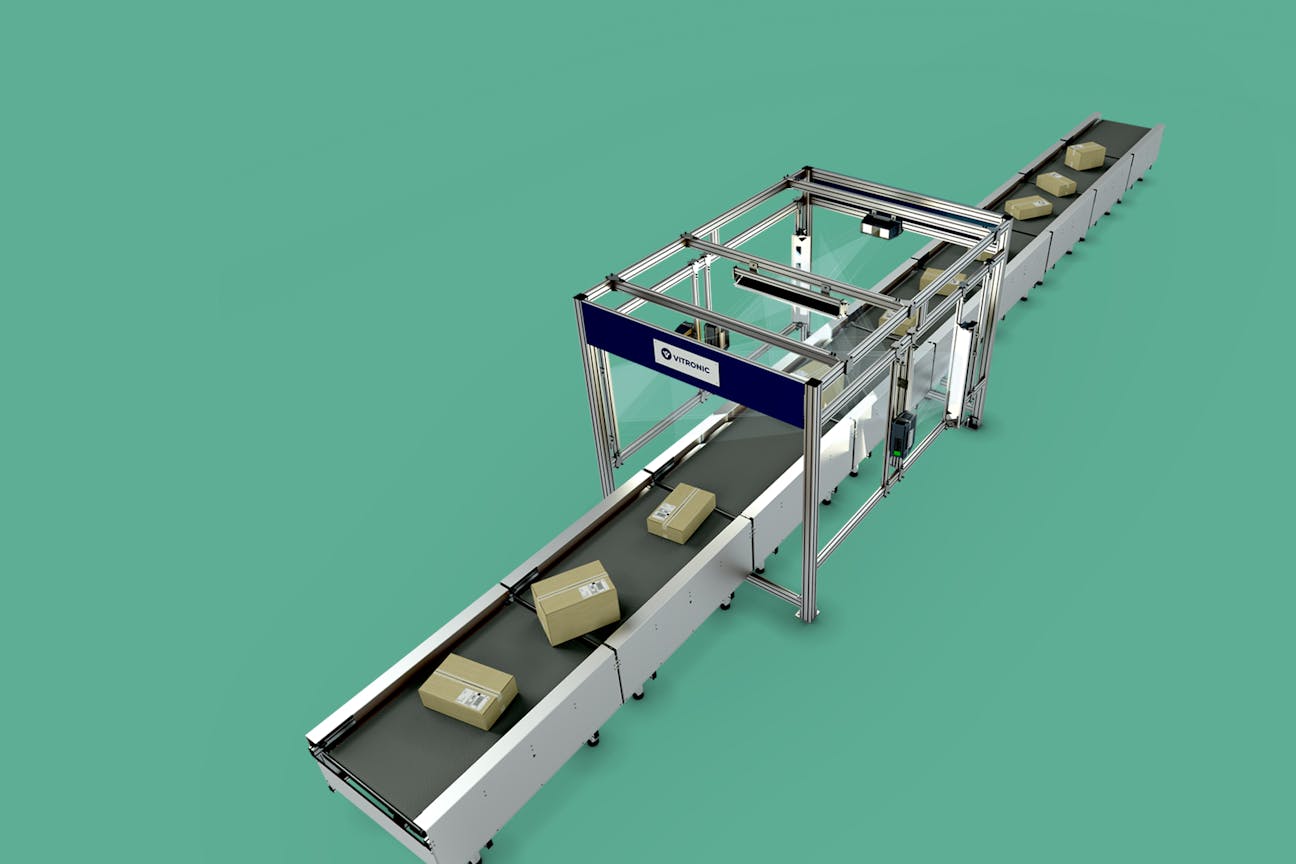

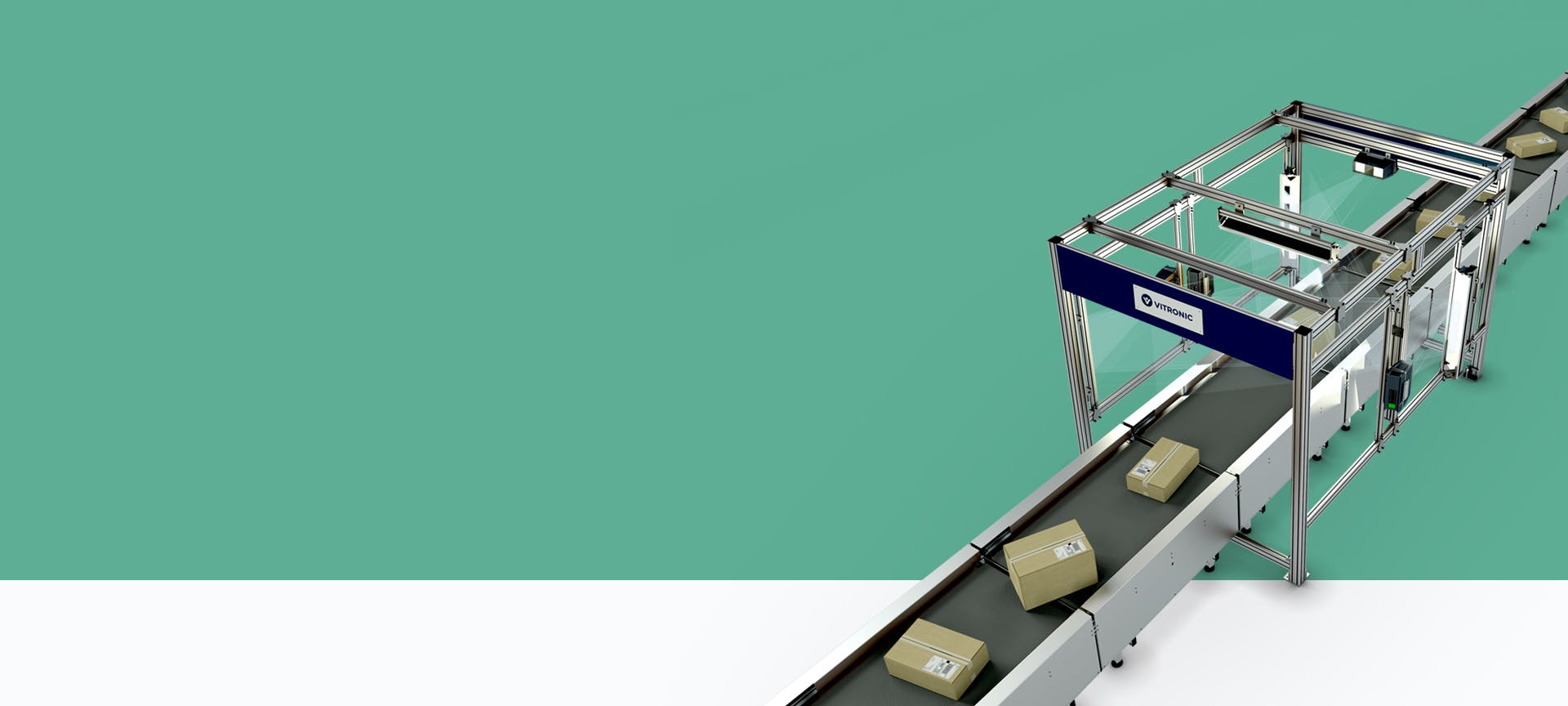

Data Capture and Documentation in Outgoing Goods Areas

Order Picking and Outgoing Goods Inspection

For Taking Away and Passing On

Brochure

Monitoring, Archiving and Data Analysis for VIPAC Shipment Recording

Brochure

VOLUMEC HD: Dimension Detection With Maximum Accuracy