SMD Reel Capture Fast, Error Free and Traceable

An Efficient Incoming Goods Process for Component Reels

SMD Reel Capture

Capture All Barcodes in Minimum Time — Without a Handheld Scanner!

More Efficiency in the Incoming Goods Department

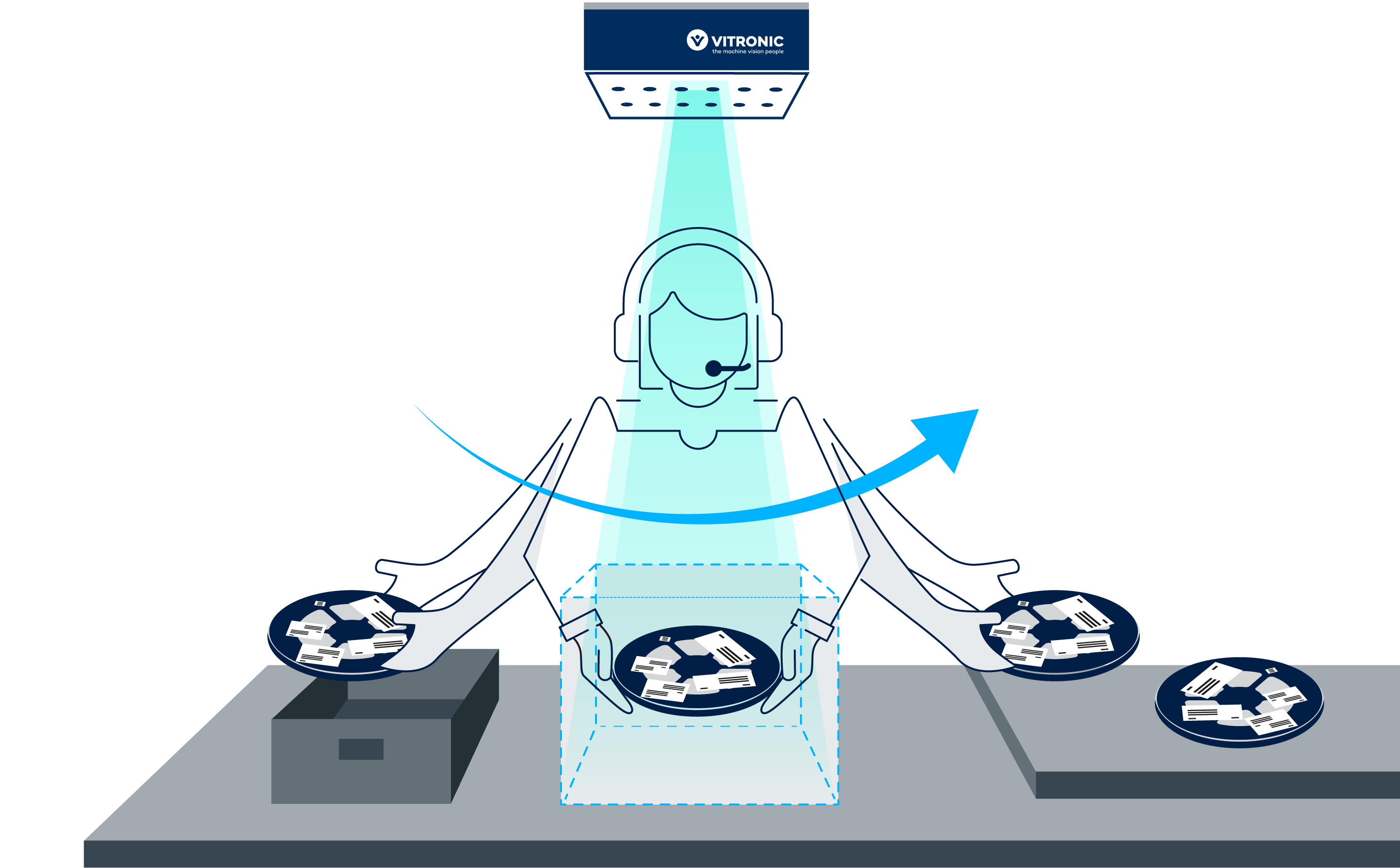

Multi-codes on SMD reels should be captured quickly and without errors. But it is simply not possible to pick up any real pace when using conventional handheld scanners. Furthermore, the high error rate is a problem with regard to traceability if not sooner. A sleek camera system on the manual workstation provides the solution for the entire process.

Fast-Paced Incoming Goods Processes at Last

Want to improve efficiency at manual workstations? This Auto-ID system eliminates the need for laborious handheld scanners and error-susceptible manual triggering for every code.

This makes it a lot quicker to capture reels. We have based our example calculation on an average of six multi-codes per reel.

- 900reels/h with an Auto-ID-camera

- 300reels/h manually

- 3× faster than manually

All Codes at Once

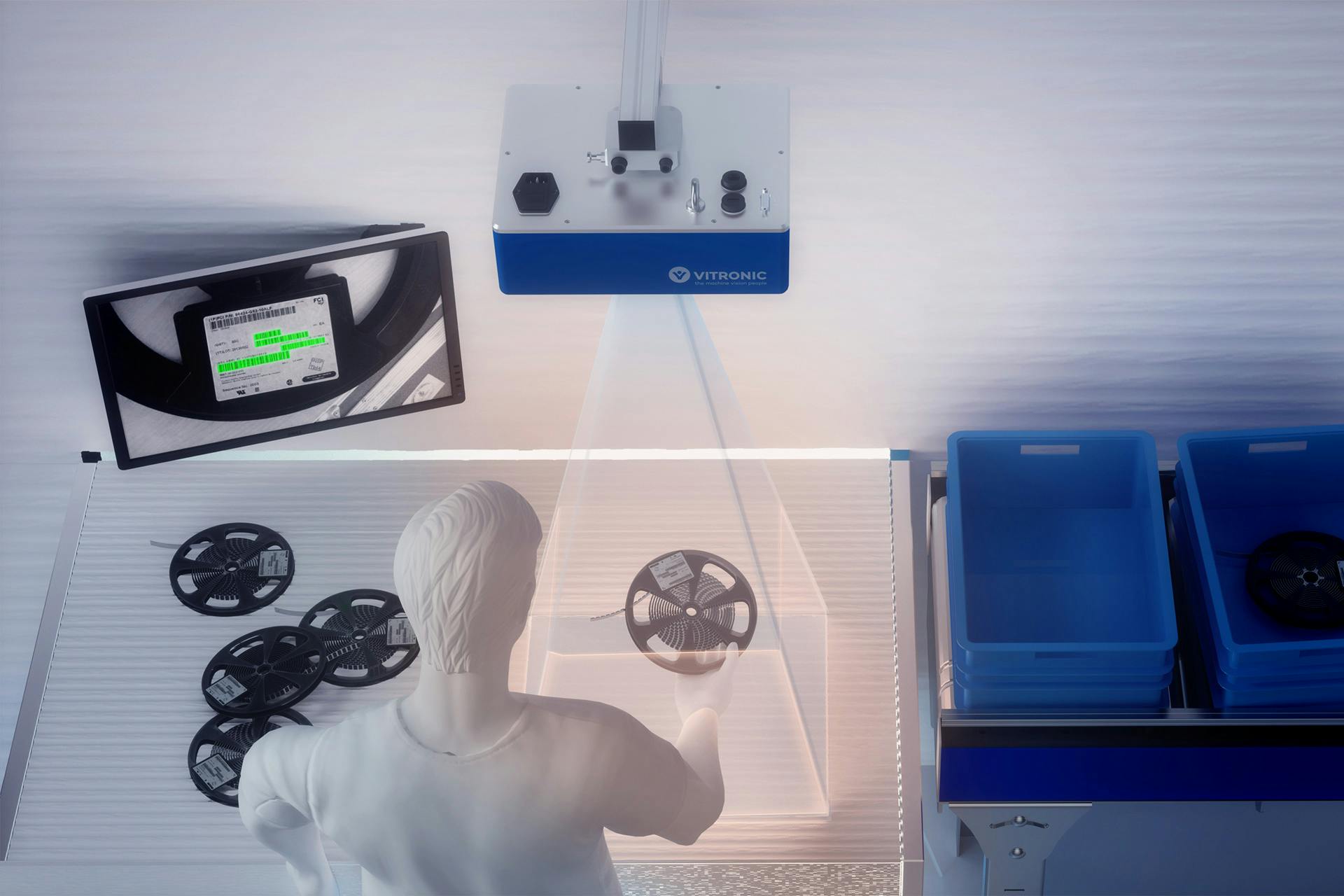

As soon as the incoming goods operator moves the SMD reel into the reading area, the camera above the workstation triggers—automatically! Acoustic signals are also emitted to assist the operator with the subsequent steps.

Whereas conventional handheld scanners only capture a single code, the Auto-ID system captures all codes on one SMD reel in a single operation.

- 4s per reel

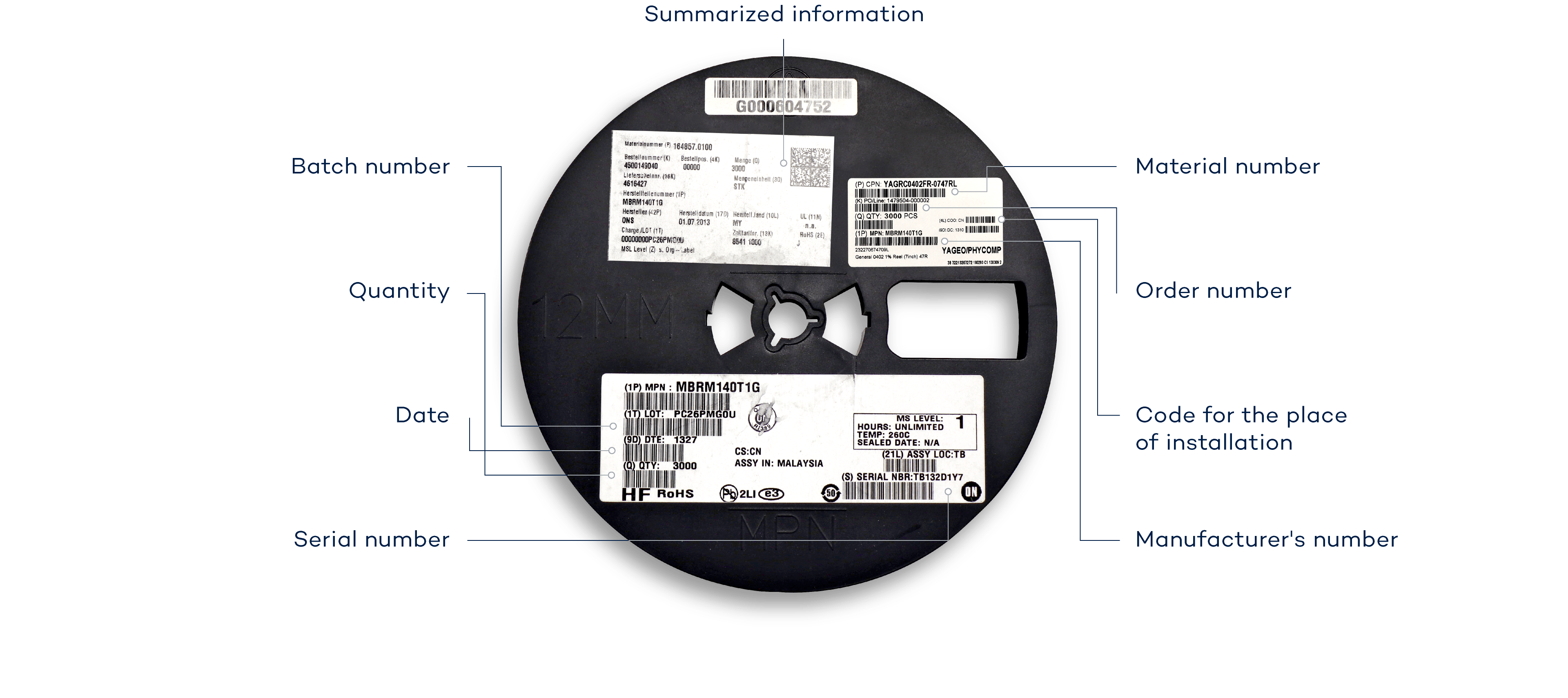

Which Data is Captured?

All data! The system reads all data in a matter of seconds. Even internal incoming goods labels are recognized and the recorded data is transferred to the ERP systems — seamlessly and irrespective of the provider.

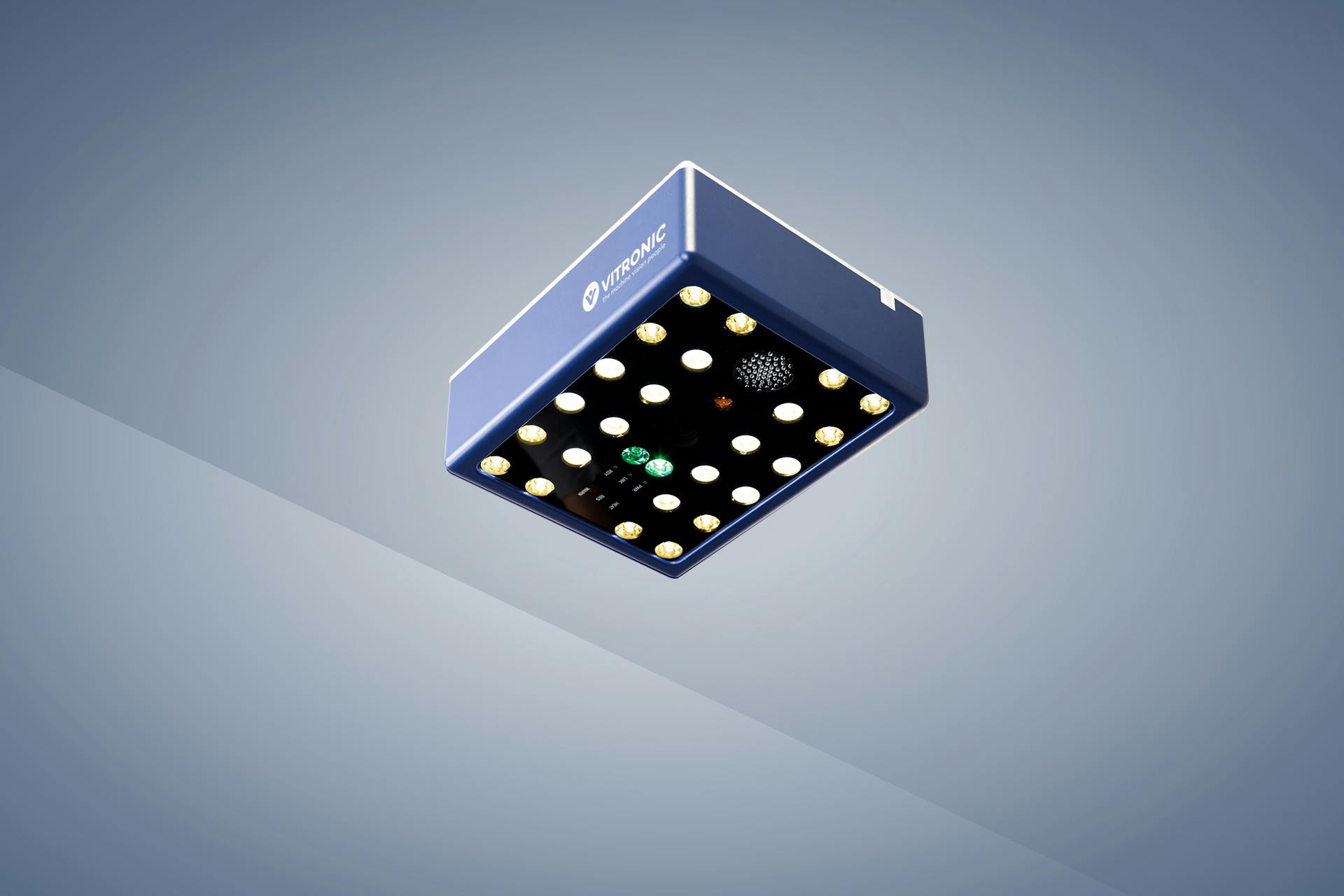

Faultless Camera Readings

SMD reels with lots of little codes printed closely together are a common occurrence—and it is easy to make errors when capturing them. The matrix camera on our Auto-ID system reads even tiny codes without failure. No codes are missed and all codes are captured correctly.

Only if all incoming goods data and master data is captured without error in the first step consequential costs can be avoided.

- Up to 10MIL code size

- 1 D + 2 Dcodes

All Batches Remain Traceable

The data captured from each reel is saved in an integrated database, where it is also available for evaluation.

EMS and distributors benefit from these data records as complete, error-free data capture and long-term archiving enables them to trace all components at any time and selectively replace defective batches.

- 100% traceability

In Brief

Carsten Astner

Sales Logistics Automation- carsten.astner@vitronic.com

- Telefon

- +49 151 6896 2325

Follow me

SMD Reel Capture: Fast and Error Free

In Brief

- 3 × faster capture

- All codes at once

- No handheld scanners

- Error-free capture

- Reliable data archiving

- Seamless traceability