Case Study Retrofitting AI-assisted particle detection

On existing blow-fill-seal production lines

At a glance

-

Documented project duration of 6 months

-

Hybrid solution of classic machine vision and AI

-

Integration into the running production line

-

Conscientiously prepared data sets as a success factor

About the customer

The company is a global leader in the manufacture of pharmaceutical and medical supply products. It operates large production lines for BFS (blow-fill-seal) containers at several locations. The company already uses systems for automated visual inspection from VITRONIC for quality control.

BFS containers have to be absolutely clean: no metal or plastic particles from the production process, dust or hairs may remain in them. Such unwanted particles, for example in infusion solutions, can seriously harm patients or even lead to their death.

For this reason, every single BFS container must be inspected after filling and sealing. Camera sensors with image processing are used for this purpose. However, harmless air bubbles, droplets or foam in and on the container can easily be mistaken for unwanted particles. This leads to a relatively high rate of false rejects.

The false reject rate was unacceptable to the producer. However, it could not be further reduced using classical image processing methods.

The solution

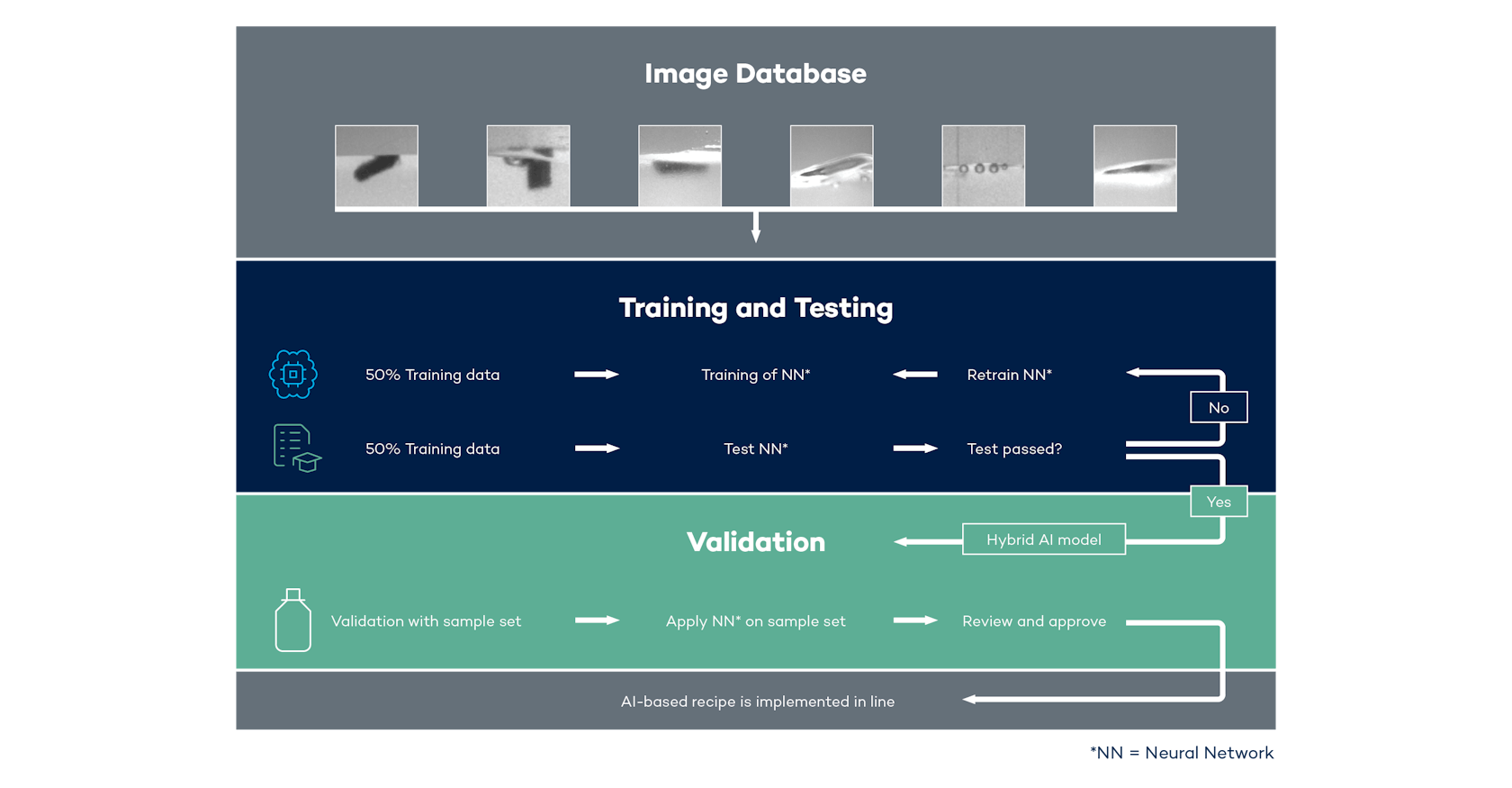

VITRONIC solved the challenge by a hybrid solution of classical image processing and artificial intelligence: The inspection system was enhanced by a machine learning component based on neural networks.

The images from the previous inspections were segmented depending on what kind of particles could be seen on it. With these images, the artificial intelligence was trained to distinguish harmless and undesirable particles. The AI model was eventually integrated into the running production lines and further refined in test runs.

In addition, higher resolution cameras were installed at the particle detection stations, with 5 megapixels instead of just 1.3 megapixels. The AI model was integrated into the existing software applications.

The inspection system was fully qualified by VITRONIC, following the GAMP®-5 guidelines for computer-aided systems in pharmaceutical environments.

In total, the project took about 6 months; installation and qualification at the production sites were completed in only three weeks. Go-live was in April 2022.

The result

Immediately after commissioning, the figures showed that the new, hybrid system was a complete success. Results were similarly good at different line speeds (with more agitated liquids within the BFS containers).

- 0.2% The false reject rate was reduced to 0.2 percent in one production line.

As in other AI projects, the quality and volume of the training data played a decisive role: only the large, conscientiously prepared data set enabled the fast results.

The project shows: classical image processing and artificial intelligence can be perfectly combined. It can be assumed that such hybrid systems can also be used in other production areas for difficult inspection tasks.

Summary

- Challenge: The inspection systems in production lines for BFS containers were generating too many false rejects due to difficult conditions.

- Solution: The systems were upgraded and an AI component was added to better distinguish harmless and unwanted particles.

- Result: The false reject rate was reduced to 0.2 percent.