Our History VITRONIC is shaping the future of automotive production

With experience and innovative strength

When VITRONIC developed its first sensors in 1984, the automotive industry was a different one. Today, the industry is in the midst of an unprecedented upheaval. Does a long company history hinder future innovations or does it even offer a springboard?

Multiple challenges for automotive production

The car is becoming a mobile computer: the current transformation from combustion engine to electric motor and digital vehicle is the most far-reaching change in the industry for a long time. The transition to e-mobility requires, among other things, completely new production processes and quality standards, particularly when it comes to joining components such as batteries and lightweight bodies.

At the same time, cost pressure in the industry is growing, driven by intense global competition. New players from China are entering the market and forcing established manufacturers to become even more efficient. More than ever, it is necessary to produce both economically and ecologically sustainably.

These diverse challenges can be mastered efficiently with high-tech solutions in combination with optimized processes that combine maximum precision and reliability with cost-effectiveness.

For 30 years, VITRONIC has been an experienced partner to its customers in the automotive sector, who benefit from the convergent knowledge of 40 years of VITRONIC: with innovative, automated systems for weld seam inspection and process monitoring.

We have been pushing the boundaries of what is feasible in weld seam inspection for over 30 years and will continue to do so in the future.

From "staircase sensor" to market leader in weld seam inspection

It all started very modestly in 1984: VITRONIC developed sensors for the production line of a wooden staircase manufacturer. 10 years later, in 1994, the engineers laid the foundation for today's success in the automotive sector. A system with multi-line seam tracking sensors inspected safety-relevant weld seams on vehicle wheels using cameras and laser triangulation.

Milestones included the first series-produced sensor in 2004, which was able to output geometric features in millimeters, as well as the automation of reworking based on the inspection results.

Today, car manufacturers and suppliers worldwide rely on VITRONIC's solutions when it comes to precision and reliability in weld seam inspection. The case study with the Polish car body manufacturer WASIAK demonstrates this impressively. Thanks to the VIRO WSI inspection system, even critical components such as battery frames are produced with zero defects.

Safe into the future with innovative solutions

To become more efficient, car manufacturers are constantly working on optimizing their production. Analyses based on "big data" have proven to be particularly effective. How can this tool also be used for welding lines?

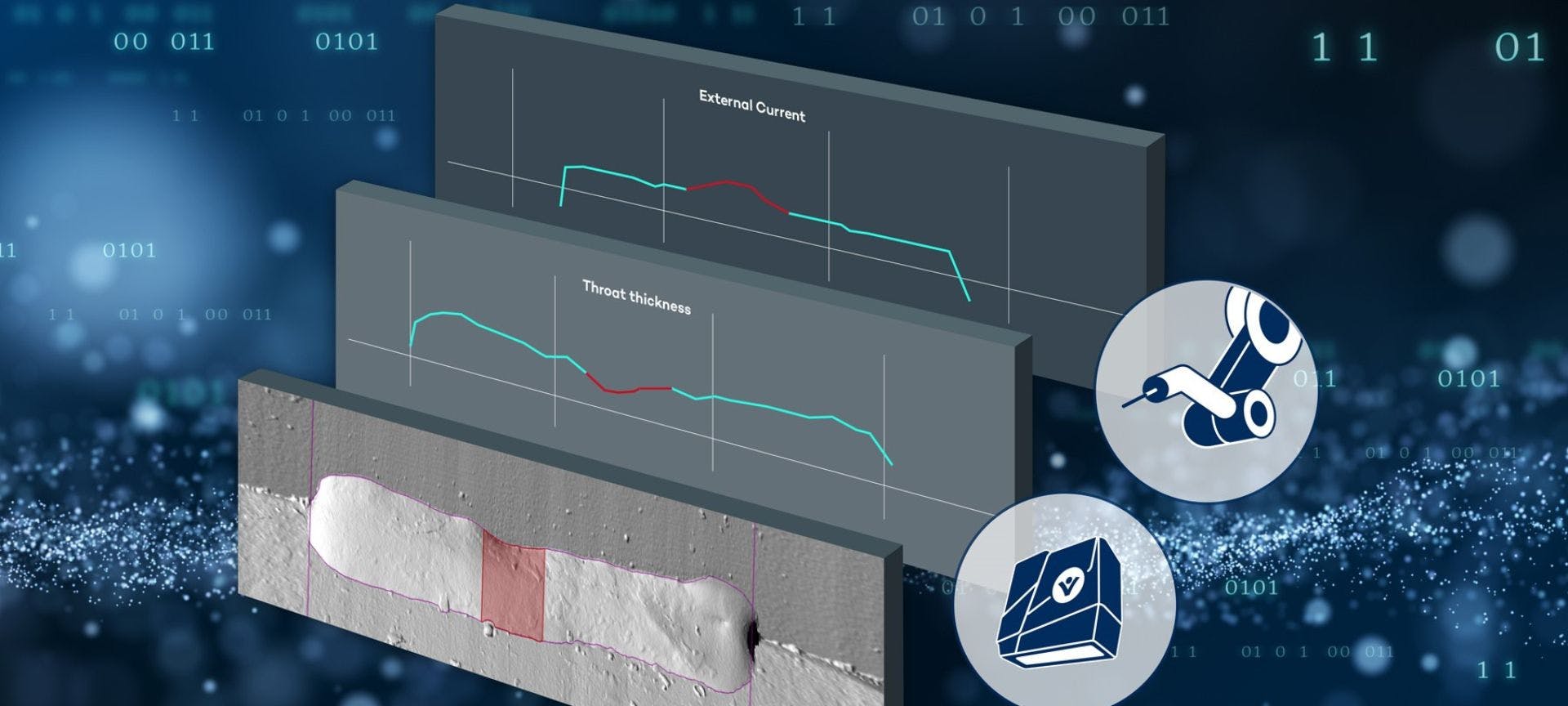

VITRONIC's Weldloop software, which was launched by VITRONIC in 2022, provides the answer to this question. It allows inspection data from the VIRO WSI inspection systems to be seamlessly linked with process data from the welding line. Quality deviations can thus be quickly recognized and their causes specifically eliminated. For users, Weldloop is an important step towards end-to-end digitalized, intelligent welding production.

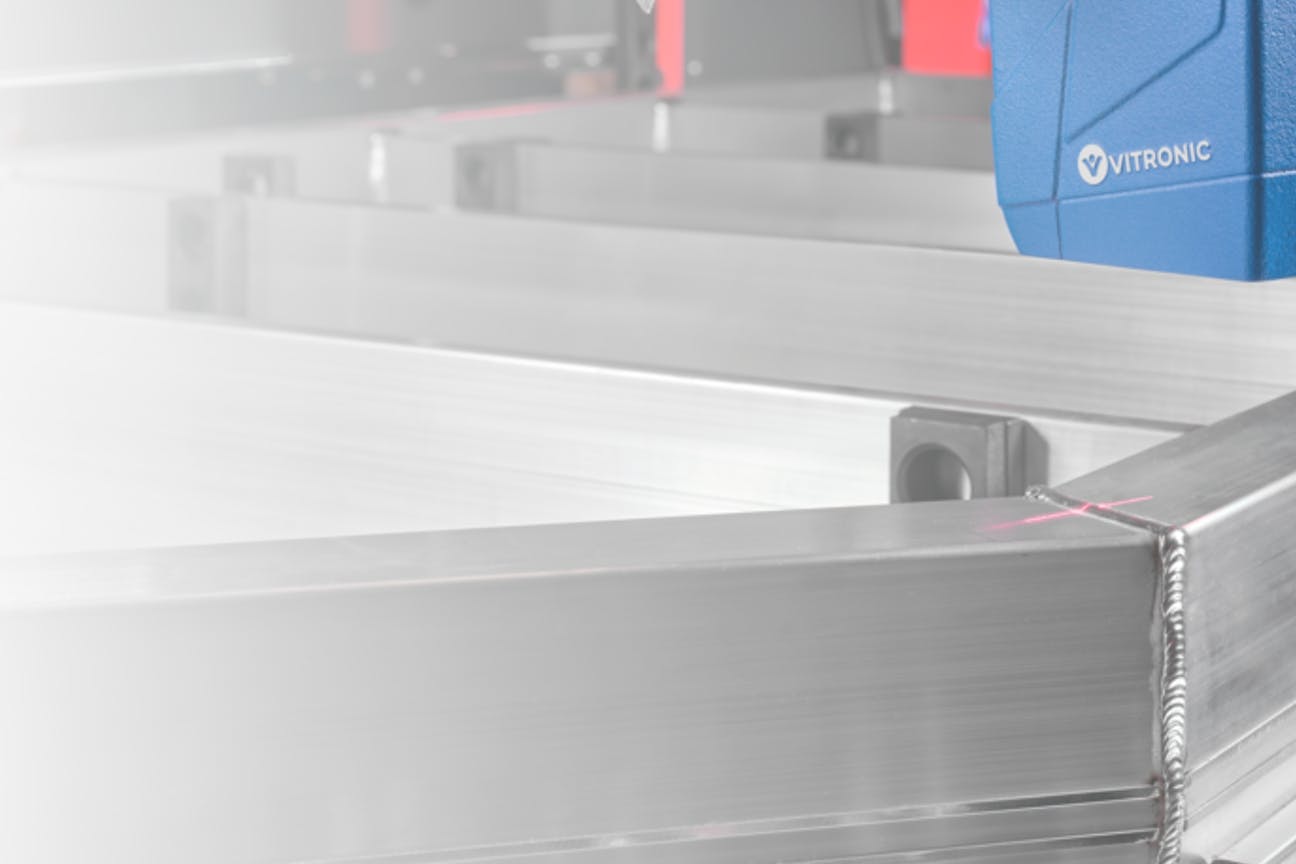

The new lightweight materials for electric cars mentioned above also bring with them new requirements: they are primarily joined by laser welding. Maximum precision is required, as even the smallest deviations can lead to quality problems or rejects. Interruptions to the high-speed lines cost money unnecessarily every time.

With the VIRO WSM system introduced in 2023, VITRONIC offers a pioneering solution for this: it monitors laser welding processes in real time and reports anomalies immediately - long before the downstream quality inspection. This enables manufacturers to achieve higher levels of automation and exploit the full optimization potential.

VIRO WSM fits perfectly into an agile, dynamic production environment. It is compatible with practically any welding system and can be integrated into an existing welding line within just one week.

Permanently pushing the boundaries of what is feasible

Even if technology has existed and been used for decades, it can still be innovative. But how can we ensure that it stays that way? We work closely with our customers and listen to them so that we can develop real solutions for real problems. We don't rest on our laurels but are constantly developing ourselves and our solutions. This is the only way we can continue to be a driver of innovation in our markets.

Since the first weld seam test in 1994, we have repeatedly pushed and redefined the limits of what is feasible. At the same time, over the decades we have gained the trust of our customers that VITRONIC is the right partner for the challenges that lie ahead.