Healthcare Medical Devices Reliable automated testing of medical devices

Patient safety is paramount in the production and assembly of medical devices. At the same time, the inspection processes must be set up economically and cost-efficiently. Test systems for automated visual inspection from VITRONIC help to ensure the highest standards of product safety and quality in the pharmaceutical industry.

1 Application in Medical Devices

As a leading supplier of machine vision systems, VITRONIC has earned a reputation as a reliable and innovative partner in a wide range of industries, including medical technology. Our automated inspection systems help ensure and optimize the quality of medical devices.

At VITRONIC, we work closely with our customers to develop customized solutions that are tailored to their exact requirements and needs. Reliable automated testing of medical devices is becoming increasingly complex and requires more and more expertise. We are proud to offer high-quality automated testing systems that help to ensure the quality of medical technology and increase the confidence of patients and medical professionals in these devices.

Automated testing of medical devices is of great importance to ensure the safety and effectiveness of medical applications. At VITRONIC, we have years of experience in the development and manufacture of Automated Visual Inspection (AVI) systems, some of which are specifically designed to meet the demanding requirements of medical technology.

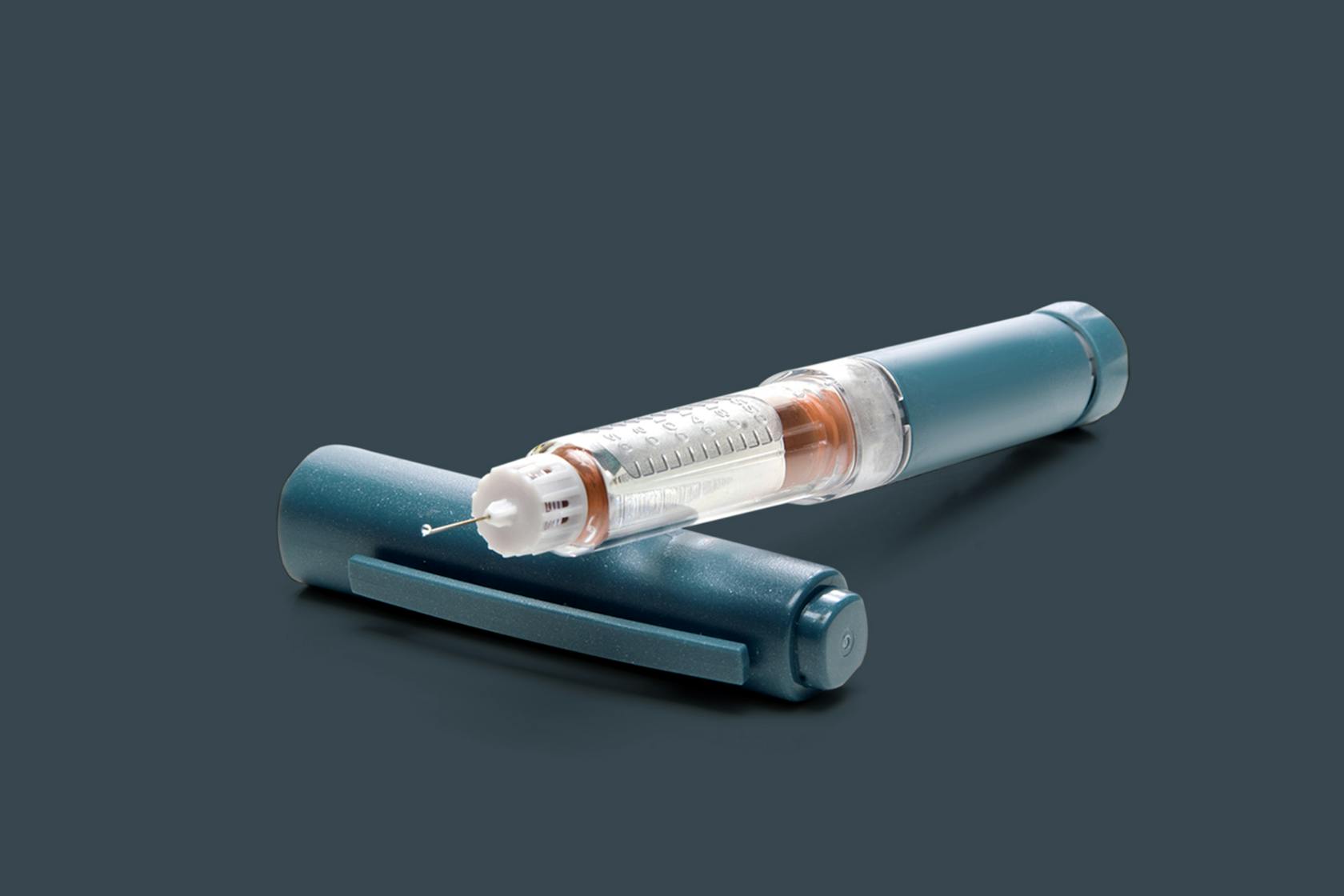

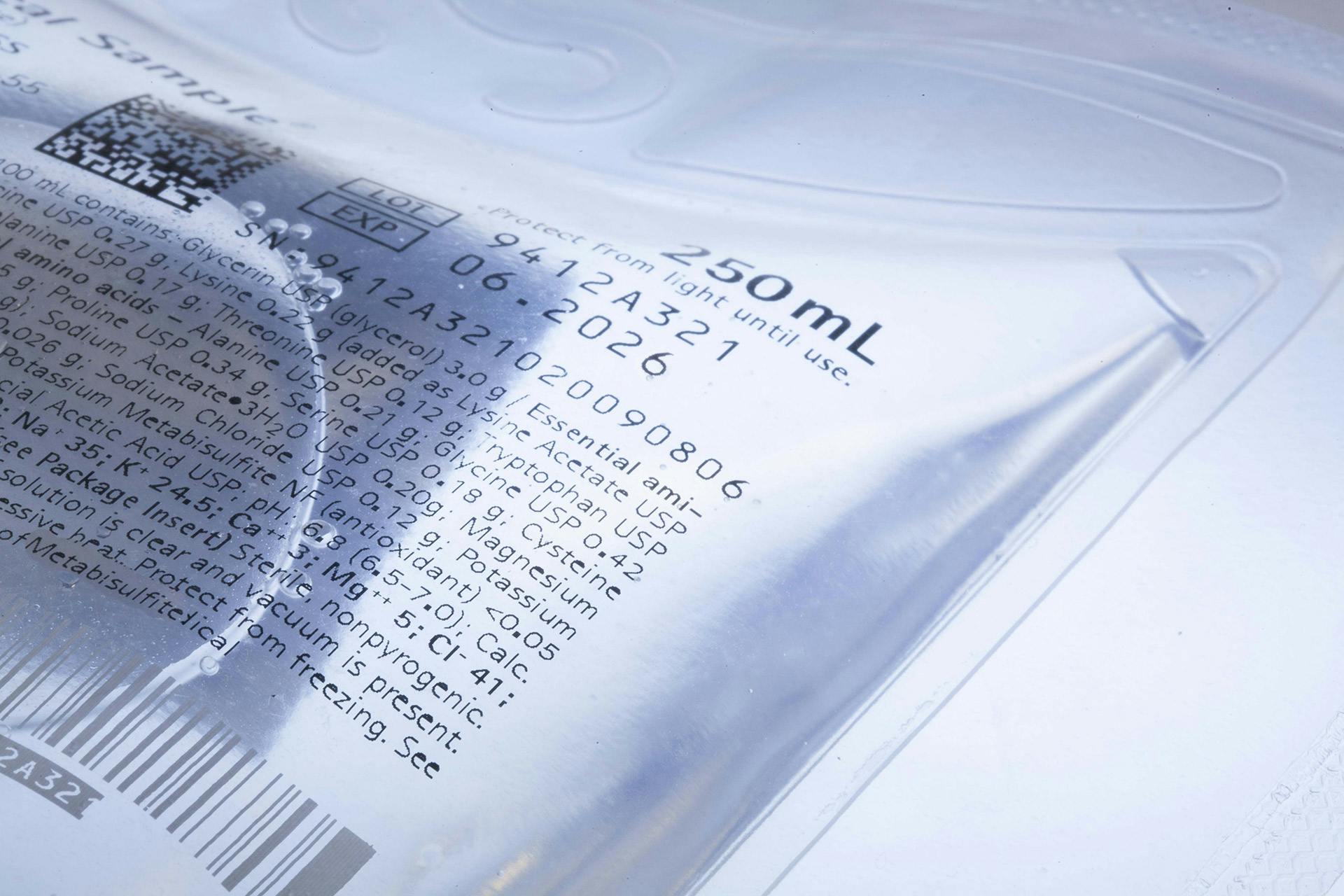

Our innovative solutions enable fast and precise inspection of medical devices such as insulin pens, syringes and injectors. With the help of our automated testing systems, critical parameters such as filling quantity, pressure or leakage can be measured reliably and accurately. VITRONIC's automated testing systems offer many advantages. They are fast, efficient and can test a high number of devices in a short time. This saves time and money and ensures that the devices can be brought to market quickly. In addition, VITRONIC's automated testing systems are extremely accurate and reliable. This ensures that the devices operate safely and effectively and meet the requirements of regulatory authorities.

For example, in the industrial testing of insulin pens, it is important that these medical devices are manufactured and tested in accordance with the requirements of the relevant regulatory requirements, such as the Medical Device Regulation (MDR) or FDA guidelines. Insulin pens are medical devices used for subcutaneous injection of insulin. They must be safe and reliable and allow accurate dosing of insulin.

Our Automated Test Systems are easy to operate and offer high efficiency in testing medical devices according to principles of the GAMP® Guide. In addition, automation of the test processes enables faster and more efficient testing of devices, helping to reduce costs and time.

If you would like to learn more about our Automated Medical Device Testing Systems, please feel free to contact us. We look forward to providing you with our expertise and experience to ensure you get the best possible solution for your testing needs.