Healthcare Pharmaceutical Packaging Automated visual inspection solutions for the pharma industry

Cost efficiency and patient safety are essential aspects to consider when implementing solutions for the automated visual inspection of pharmaceutical packaging. With our systems, you can monitor the entire process chain reliably and efficiently. As a result, excellent product safety, low costs, and compliance can be realized.

4 Applications in Pharmaceutical Packaging

Advanced Inspection Systems for Pharmaceutical Packaging

VITRONIC is a leading provider of advanced inspection systems for pharmaceutical packaging. With a focus on quality and precision, we offer state-of-the-art solutions to ensure the integrity and reliability of parenterals and ampules. Our automated visual inspection (AVI) systems leverage cutting-edge technology to meet the highest industry standards and optimize your manufacturing process. Read on to explore our comprehensive range of visual inspection solutions for pharmaceutical packaging.

At VITRONIC, we understand the critical importance of quality inspection in the pharmaceutical industry. Our inspection systems are designed to detect even the smallest defects and deviations in parenterals and ampules, ensuring the integrity of the product and compliance with regulatory requirements. Leveraging advanced image processing algorithms and artificial intelligence, our systems provide accurate and reliable inspection results, minimizing the risk of product recalls and enhancing overall product quality.

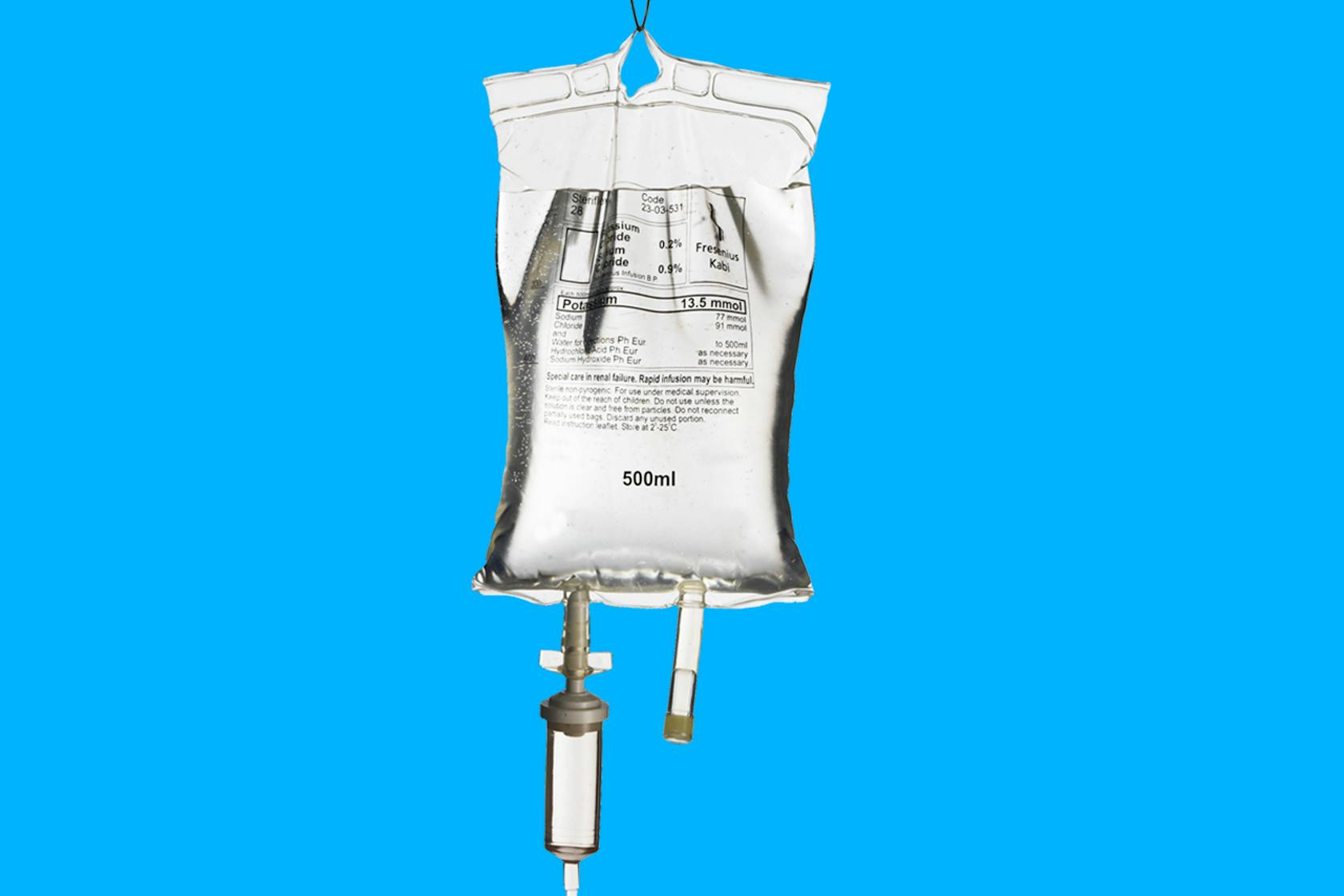

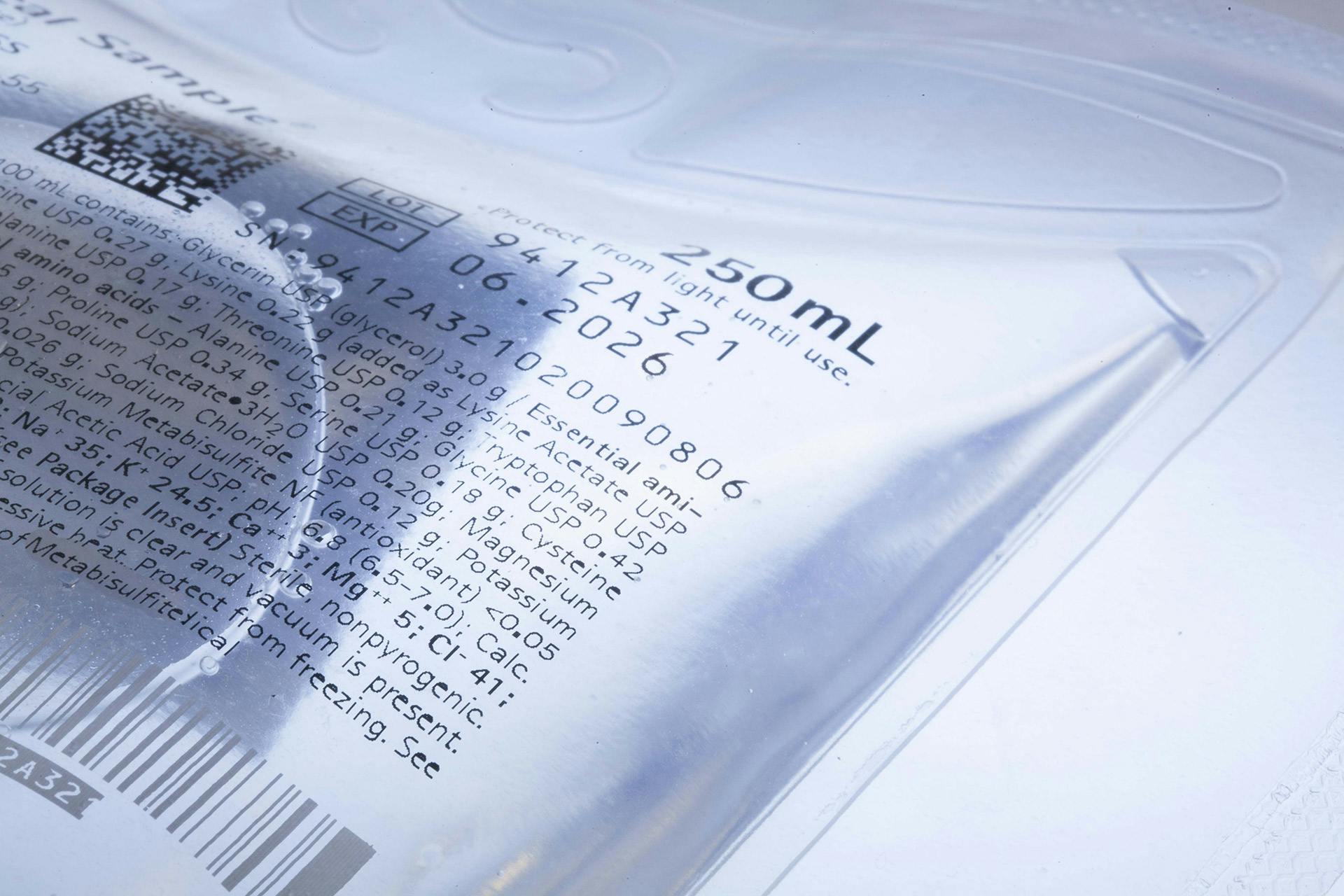

Our automated inspection systems for parenterals combine high-speed inspection capabilities with exceptional accuracy. By leveraging advanced optical technologies and precise imaging techniques, we can identify defects such as particles, impurities, and cosmetic flaws. With our comprehensive analysis and classification tools, you can confidently maintain the highest quality standards throughout the manufacturing process, such as the inspection of vials and crimp caps.

VITRONIC's inspection systems for ampules offer comprehensive and efficient solutions for visual inspection. Our advanced technology enables the detection of defects such as cracks, leaks, and contamination, ensuring the integrity of the ampules. By implementing our automated inspection systems, you can significantly reduce the risk of product recalls and enhance customer satisfaction, while complying with industry regulations, such as the Medical Device Regulation (MDR) or FDA guidelines.

Our automated inspection systems provide a high-speed and accurate inspection process for parenterals. By incorporating advanced machine vision technology, we can effectively detect defects, foreign particles, and contaminants. Our systems seamlessly integrate into your production line, enabling real-time monitoring and continuous quality control. With VITRONIC's automated inspection systems, you can streamline your manufacturing process, increase efficiency, and reduce costs.

VITRONIC offers cutting-edge inspection systems specifically designed for pharmaceutical packaging. With our advanced technology and expertise, we ensure the highest quality standards for parenterals and ampules. By implementing our visual inspection solutions, you can enhance your manufacturing process, minimize the risk of defects, and comply with industry regulations. Trust VITRONIC to provide reliable and efficient solutions for pharmaceutical packaging quality inspection.