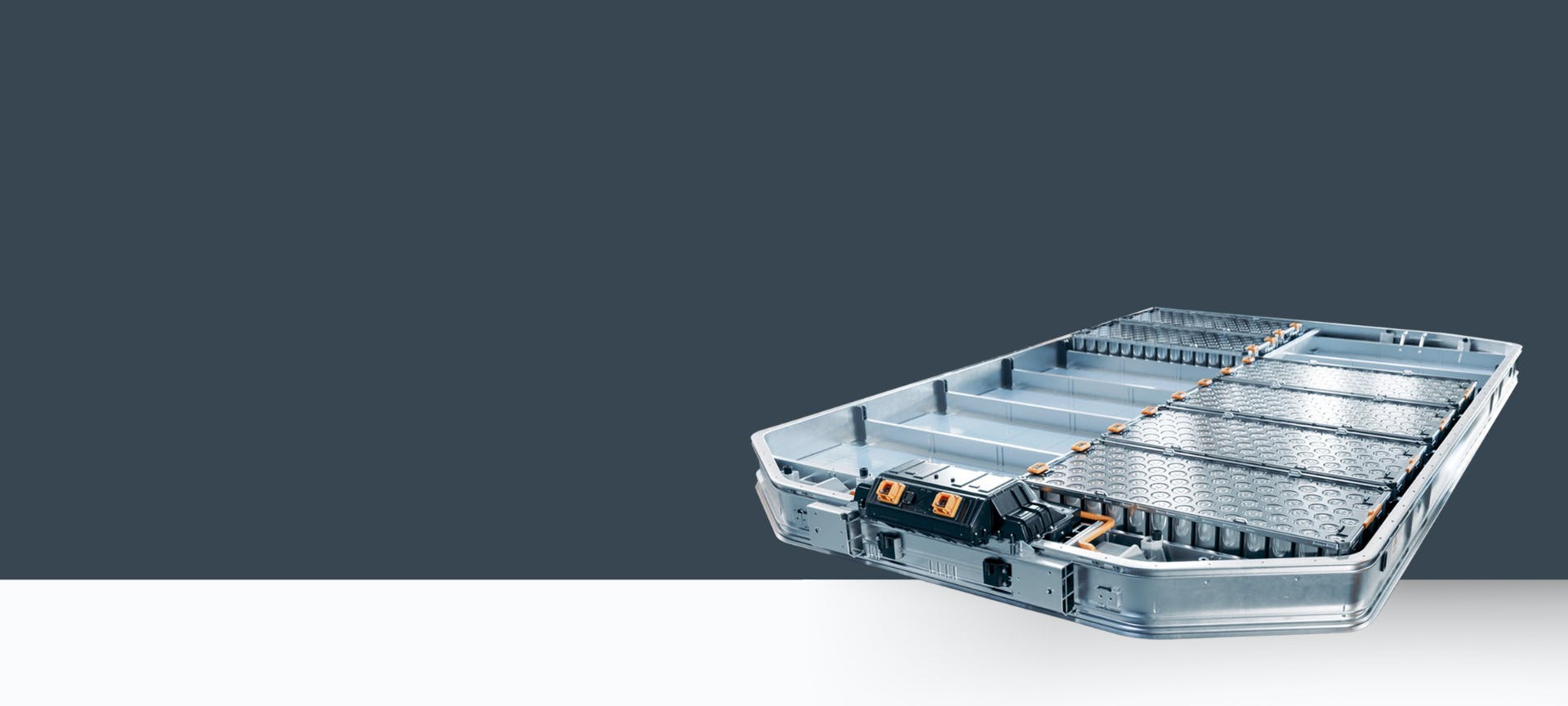

Deliver battery trays with 100 percent flawless welds.

VITRONIC inspection systems detect the smallest welding defects: seams that are too thin, pores, incorrect connection angles and much more. They master all welding processes that are used: MIG/MAG, laser, laser hybrid and friction stir welding.

Through monitoring, deviations in laser welding can even be detected in real time during the welding process.