Only with a consistent concept from design and material selection to production and quality control can manufacturers meet the highest safety requirements for battery housings.

Smart Production Requirements for safe e-car battery housings

A holistic safety concept includes material selection, design, and manufacturing.

The battery is the central component of an electric car. At the same time, it can pose a great danger in case of an accident. A complex system of mechanical and electrical components as well as software therefore protects the battery.

The safety concept includes the housing on the underside of the vehicle in which the cells are installed. How does safe battery housing design look like, and how do manufacturers ensure quality in production?

Crash safety and fire protection

The battery housing of an e-car contributes to vehicle safety primarily in two aspects: First, it protects the battery against damage in the event of an accident, and second, it protects the car passengers if the battery catches fire.

In frontal and side crashes, as well as in the particularly dangerous side pole impact (see illustration), the housing must withstand to protect the battery cells from damage. If they are severely damaged and the separators between the anode and cathode are broken, a short can easily occur and ignite the cell. The worst case: a thermal runaway, when the battery's cells catch fire and burn out. Temperatures of over 1,000 degrees arise; the fire can only be extinguished with special equipment.

If this happens, the materials must withstand a few minutes and enclose the fire. Any gases that arise must be vented to the outside in a controlled manner. This gives the passengers the opportunity to escape to safety. That's why the requirement for battery housings is: they must be hermetically sealed, ensured by flawless designs and weld seams. Openings in the battery box can be secured by plastic granules that melt under heat and seal the opening.

The cover of the battery housing also protects the battery from external fires; for example, if fuel from an involved accident vehicle leaks out and burns. Neither dirt, stones, nor splash water must get inside; these can start fires or at least impair the function of the battery.

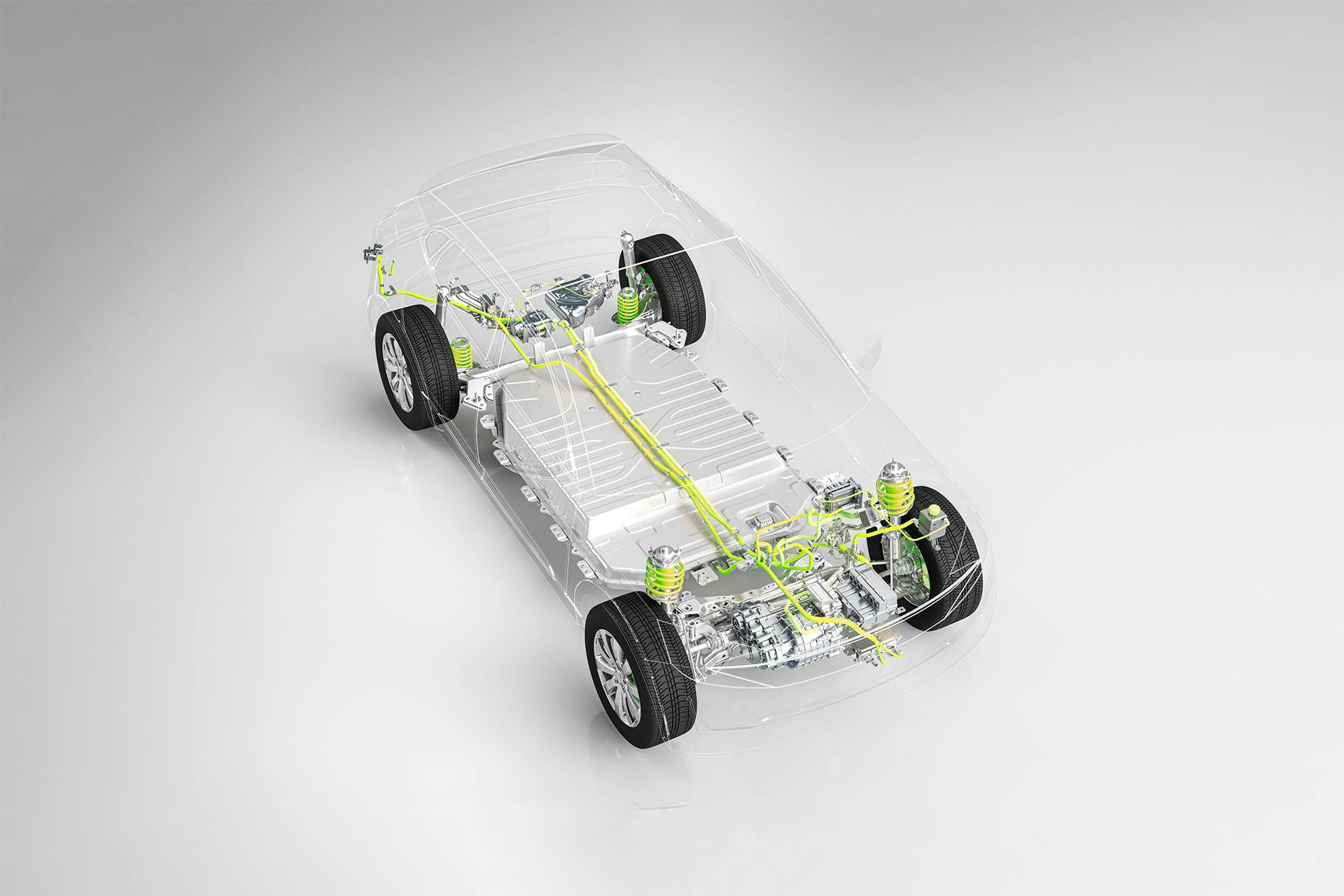

Battery housings are integrated differently depending on the vehicle concept. In some models, they are simply hooked into a complete chassis; in this case, the housing itself and the conjunctions must be stable.

Usually, battery housings are integrated into the load-bearing vehicle structure. They then contribute to the overall stability of the vehicle while driving and in the event of an accident, and absorb some of the impact energy.

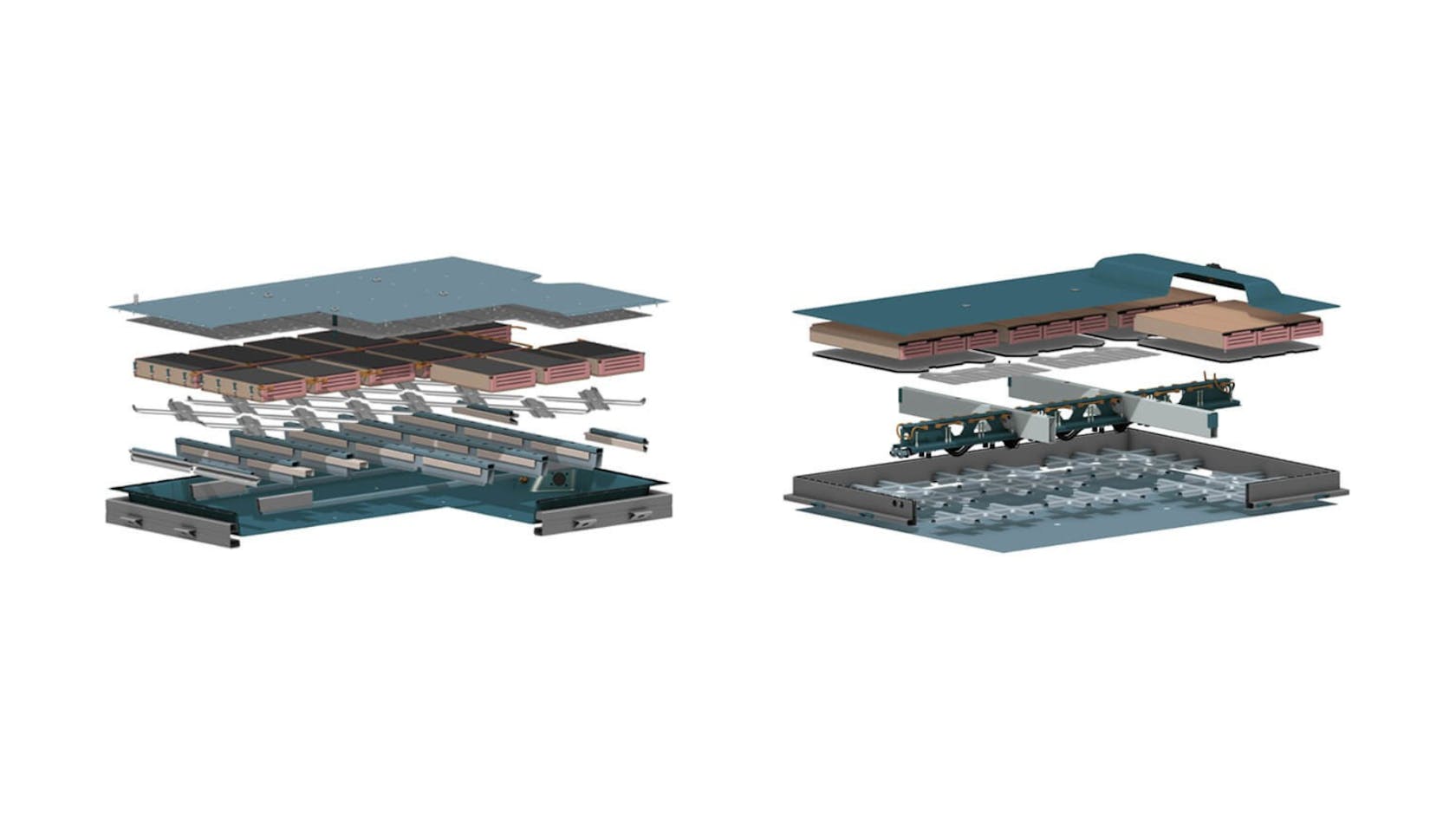

Some automotive suppliers build so-called rolling chassis: ready-to-run platforms on which car bodies can be built. (See illustration.) The battery housings are already deeply integrated in the chassis.

Safe design and materials

For safety, the design of the battery housing can’t be considered isolated. The vehicle and battery concept must be planned together. In a vehicle with a highly rigid body, the battery housing must withstand less in the event of a collision. On the other hand, if the vehicle structure is softer, it needs a more stable battery housing. If the vehicle underbody is thicker, it may be possible to construct the lid of the battery housing to be slightly thinner. And so on.

Basically, two types of designs can be distinguished. In the tray design, all components are mounted in a tray made of sheet steel, with a lid on top. The tray is made in one piece and is therefore extremely safe and stable. However, this design is only suitable for high-volume series production, where all battery housings have the same dimensions.

More flexible are modular constructions for platform production, consisting of frame, lid, and base plate. Stability in this design is ensured by numerous welded longitudinal and transverse braces, plates, and stiffeners.

The specified maximum weight and cost are other factors that influence development. Lighter materials tend to be more expensive and require more elaborate design to achieve the same level of safety.

Roll-formed steel or extruded aluminum profiles and sheets are generally used for the components, also in combination. So-called sandwich profiles consist of thin sheets with a filling of metal or polymer foams. They are primarily used for the housing base plate, which must be particularly robust. Manufacturers are already experimenting with new materials such as Kevlar, carbon, various plastics and composite materials that could offer high safety at low weight.

Meticulous manufacturing and quality assurance

The braced construction of the battery housing consists of numerous parts, sometimes 150 and more. Any faulty weld or forgotten screw can ruin the safety concept. Conscientious series production and quality assurance are therefore ultimately responsible for how safe the battery housing really is in everyday use.

Every battery box must pass a leak test at the end of production (end-of-line): Gas or air is forced inside under pressure. If the housing can hold the pressure for a certain time without gas leaking, it passes the test.

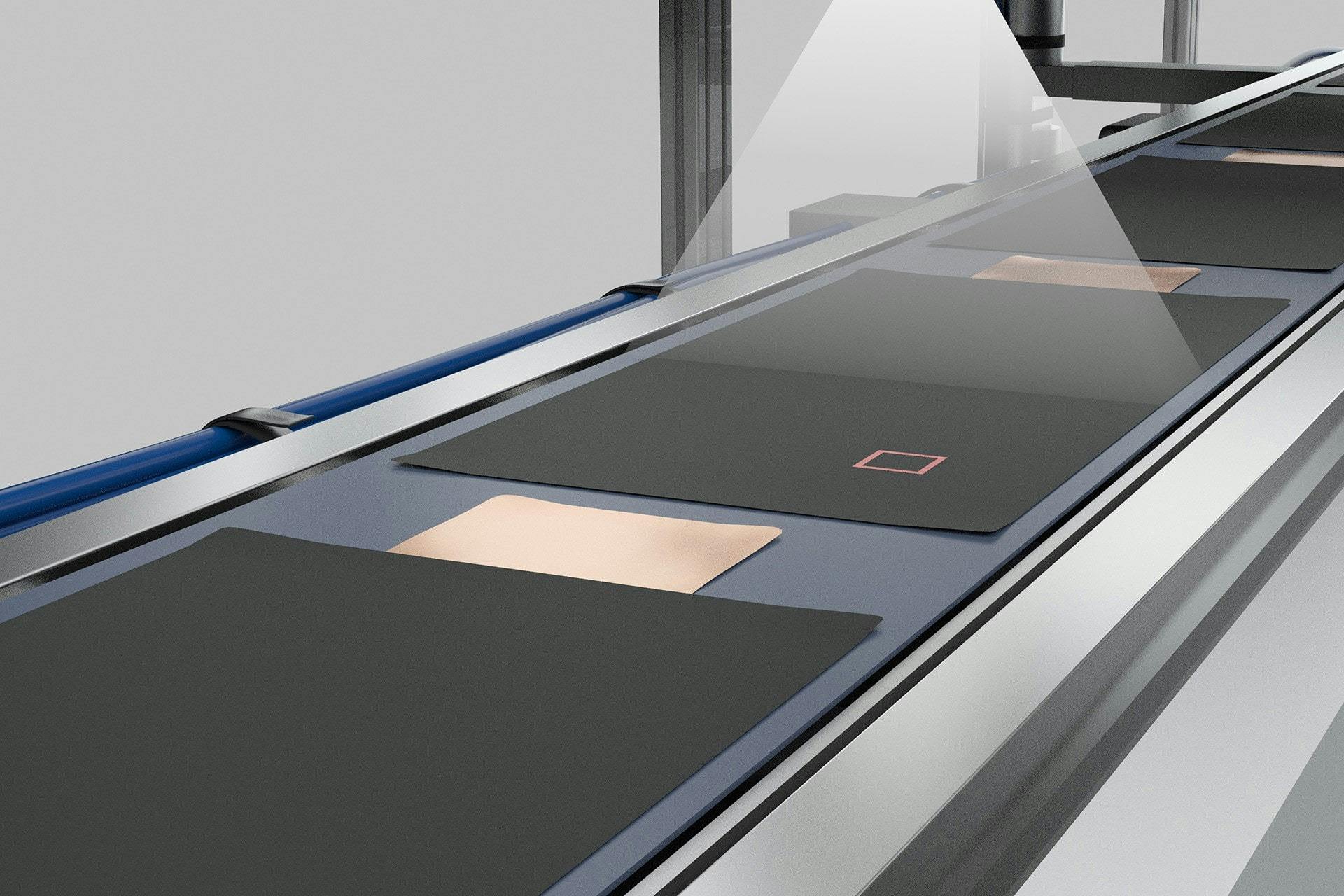

The weld seams in particular are critical for the tightness and stability of the battery housing. They must be inspected continually. Camera sensors with laser triangulation and 3D image processing inspect the more than 150 weld seams directly in the production line (in-line) and find the smallest defects, which can then be reworked.

Optical, automated in-line inspection systems are increasingly taking the place of manual visual inspections or spot checks. They can detect, for example, whether all cell modules are present or screws are loose, or whether dirt particles and other foreign bodies have entered the battery box. Such systems can combine two seemingly contradictory goals: On the one hand, zero-defect tolerance and maximum safety for e-car passengers and other road users, and on the other, efficient series production at the lowest possible cost.

We thank you for your kind support in the preparation of this article:

EDAG ENGINEERING GmbH

Mr. Andreas Pesl, Head of Department Energy Storage & Fuel Cell Systems

Mr. Simon Hallermeier, Team Leader Component Development & Integration, Department Energy Storage & Fuel Cell Systems

voestalpine Stahl GmbH

Ms. Andrea Tuksa, Technical Customer Service Automotive

Ms. Martina Kalteis, Sales Manager Automotive

Conclusion

In short

- Battery housings must protect the battery from damage and delay the spread of fire.

- For the safety concept, the vehicle structure, materials and design of the battery box must interact.

- Automatic testing systems control the quality of all components during production.