Automotive VIRO WSM supports robust laser welding processes in battery production

European manufacturers of e-vehicle batteries have to catch up in terms of efficiency

More than 20 so-called gigafactories for the production of e-vehicle batteries are currently being planned in Europe. The local industry wants to grab its slice of the pie and build more robust, independent supply chains.

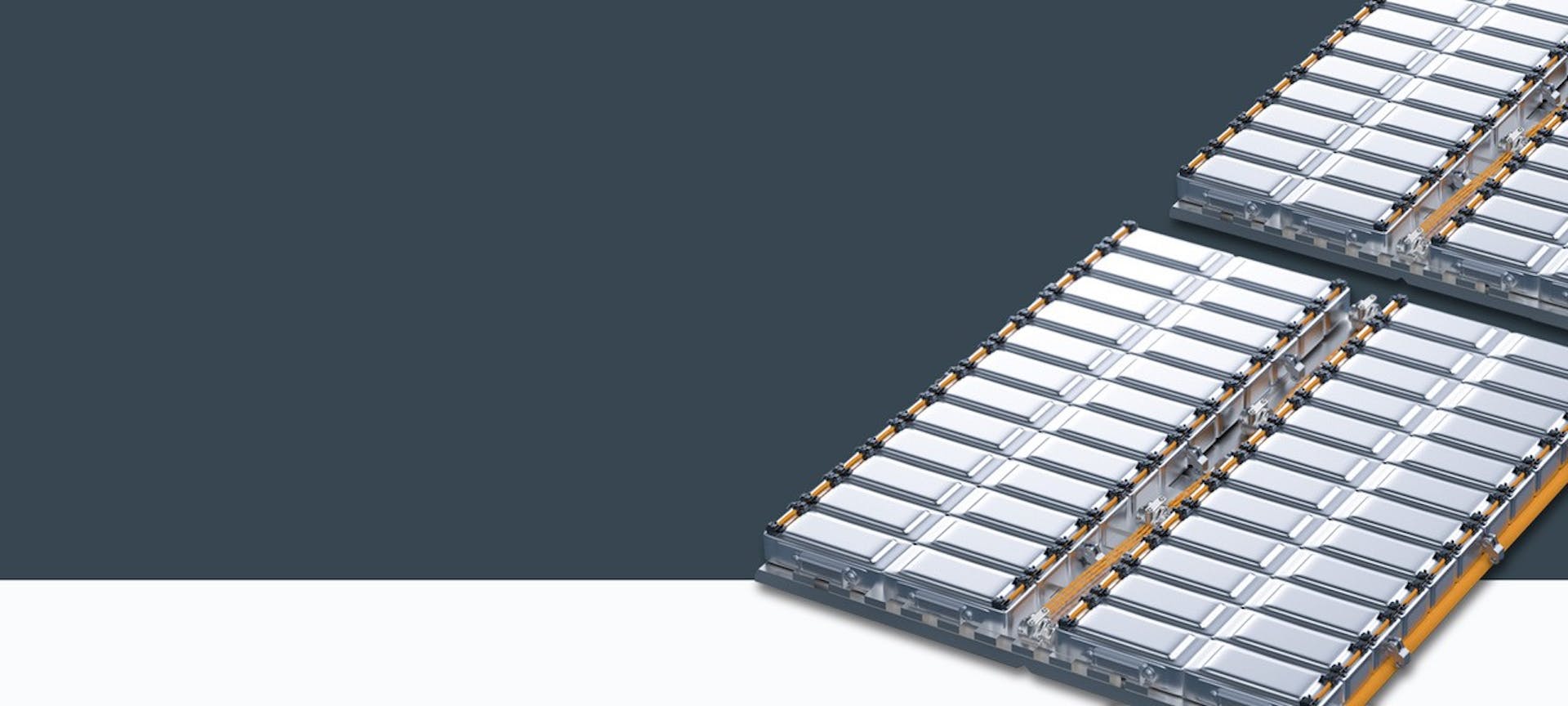

In the production of e-vehicles, the battery plays the leading role: on the one hand, it is currently the most expensive of all components. For another, it directly affects the performance, driving experience and durability of the vehicles. Flawless and durable batteries are therefore a key factor if European manufacturers want to maintain their dominance in the automotive market of the future.

But compared to combustion technology, European manufacturers still have relatively little experience with battery production. They are still struggling with quality problems in many places and need to become much more efficient - as quickly as possible.

VIRO WSM: Robust, efficient laser welding processes through real-time monitoring

In laser welding, for example, the most important joining process in battery production, there is still huge potential for optimization. Mainly lightweight materials are used in batteries and battery housings. Laser welding allows thin and small components to be joined precisely, at high speed. To leverage the technology, however, the processes must function reliably.

However, for technical reasons, the laser welding process cannot be visually inspected during operation. Defects are therefore only detected during a subsequent visual inspection of the workpieces: By then, further rejects have already been produced and the line must be stopped to search for the cause.

With VIRO WSM from VITRONIC, such expensive interruptions can be prevented. The inspection system monitors the welding process in real time by using a sensor to constantly measure several spectral ranges of light and heat emissions relevant for quality of weld seams in battery production. The system reports anomalies outside the tolerances - they indicate potential quality problems.

NOK parts can thus be immediately detected, automatically rejected and rewelded. Causes of defects can be identified and resolved more quickly before further defects are produced. All measurement data are documented and are available for quality audits as well as for data-supported process optimization.

Thus, VIRO WSM supports manufacturers in delivering batteries of consistently high quality. At the same time, robust automated processes have a direct positive impact on production volumes and costs, and thus on competitiveness.

Leading Asian manufacturers have been using the system for years

The technology behind VIRO WSM has been tested and used for years. Leading manufacturers of batteries and components in Asia rely on it including companies such as LG Energy Solution, SK ON, Samsung SDI, and Hyundai Mobis.

The flexibility as well as the ease of use contributes to the success of the solution. VIRO WSM is compatible with any welding solution and requires hardly any space in the welding line. Therefore, it can be easily retrofitted. Commissioning takes only about a week.

VITRONIC will present the system for the European market for the first time at Battery Show Europe. The trade show will take place from May 23 to 25 in Stuttgart. Interested parties can visit VITRONIC in Hall 6 at Stand A60 or make an appointment in advance via the company's event page.

About VITRONIC

VITRONIC is the world's leading innovation driver for machine vision, enabling its customers to master the challenges of tomorrow.

The global group of companies develops forward-looking solutions in the form of specialized products and software for image-based quality inspection, identification and process optimization, which find application in the growth sectors of automation and traffic engineering.

VITRONIC solutions make an important contribution to helping shape a safe and sustainable world. The existing limits of what is economically feasible are constantly being questioned in order to achieve the highest quality and productivity, for example in the production of automotive and pharmaceutical companies. Worldwide, Auto-ID solutions in logistics centers and at cargo airports, take over the reliable and efficient recording of shipments and thus ensure a transparent flow of goods.

In the transport sector, VITRONIC offers leading technology for increased safety on the roads, for optimizing traffic flow and for recording road usage.

Open and honest dealings with our customers form the foundation for jointly exploiting technological and process potential to the full. Joint success forms the basis of long-term cooperation with companies such as B. Braun, BMW, Daimler, DHL, UPS, Fresenius and Sanofi as well as with public clients.

Since its foundation in 1984, VITRONIC has been growing continuously for 40 years. The current annual turnover (2023) is above 240 million EUR and the company is currently represented on five continents in over 80 countries with approximately 1,400 employees. Since 2024 the company is part of ITIS Holding, leveraging the strengths of both entities, creating a strong end-to-end ITS and automation provider.

Development and production of VITRONIC systems are located at the company headquarters in Wiesbaden. VITRONIC subsidiaries span across all continents, including North and South America, Europe, Asia, Africa, and Oceania. Additionally, a global network of sales and service partners ensures localized support for international customers.